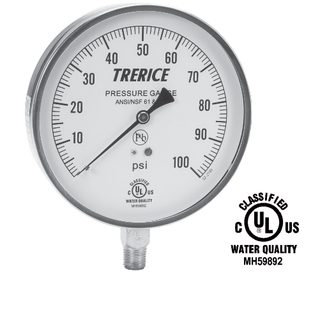

If you rely on pressure gauges to keep your systems running smoothly, knowing when to replace your Trerice Pressure Gauge is crucial. These instruments help monitor pressure in various industrial and commercial settings, and their accuracy can make or break your operations.

In this blog, we’ll walk you through the signs to watch for, why timely replacement matters, and how to keep your system performing at its best.

Why Accuracy Matters in Pressure Gauges

A Trerice Gauge provides vital information about pressure levels in pipes, tanks, and other equipment. When the gauge is accurate, you can avoid costly downtime, equipment failure, and safety hazards. Over time, however, gauges can lose accuracy due to wear, environmental factors, or mechanical issues. If you ignore these signs, your readings may become unreliable, leading to poor decisions and possible damage.

Keeping an eye on your gauge’s accuracy is not just a best practice; it’s essential for maintaining system integrity. The more precise your readings, the better you can control pressure and prevent problems before they happen. So, understanding when to replace your Trerice Gauge can save you time and money.

Signs Your Trerice Pressure Gauge Needs Replacement

How do you know it’s time to swap out your pressure gauge? Here are some clear indicators:

- Inconsistent Readings: If your gauge fluctuates erratically or shows pressure levels that don’t align with other instruments, it may be failing.

- Physical Damage: Cracks, corrosion, or broken parts on the gauge face or casing can compromise its function.

- Stuck Needle: A needle that doesn’t move or is slow to respond is a warning sign.

- Calibration Issues: If recalibration attempts fail or the gauge drifts quickly after adjustment, replacement is a better option.

- Age: Even if your gauge looks fine, older units are more prone to inaccuracies and wear.

Checking for these signs regularly ensures you don’t miss the moment when replacement is needed.

How to Extend the Life of Your Trerice Pressure Gauge

Replacing your gauge at the right time is important, but you can also take steps to extend its lifespan. Proper installation and maintenance play key roles here.

- Avoid Overpressure: Never expose the gauge to pressures beyond its rated capacity.

- Use Snubbers or Dampeners: These devices protect gauges from sudden pressure spikes.

- Keep Clean: Dirt and debris can affect gauge performance. Regular cleaning helps maintain accuracy.

- Calibrate Regularly: Scheduled calibration checks keep the gauge readings trustworthy.

- Choose the Right Model: Select a Trerice Gauge designed for your specific application and environment.

Following these guidelines will keep your gauges working longer and save you money over time.

Why Choose Lehigh Valley Valve for Your Pressure Gauges

At Lehigh Valley Valve, we understand how important accurate pressure readings are to your operations. We don’t just sell products; we offer full support from start to finish. Whether you need a new Trerice Gauge or help maintain your current equipment, we are here to assist.

Our service includes expert advice, fast shipping, and a wide range of products for industrial, commercial, waterworks, and HVAC markets. We are committed to providing quality instruments that meet your needs and exceed your expectations.

The Bottom Line

Replacing your Trerice Pressure Gauge at the right time keeps your systems safe, efficient, and reliable. Look out for signs like inconsistent readings, physical damage, or calibration problems. Maintain your gauges properly and trust experts like Lehigh Valley Valve to supply the right equipment and support. When you choose us, you get more than just parts and you get a partner dedicated to your success.

Contact Lehigh Valley Valve today to learn more about our selection of Trerice Gauges and how we can help keep your operations running smoothly. Your system deserves the best, and we are ready to deliver it.