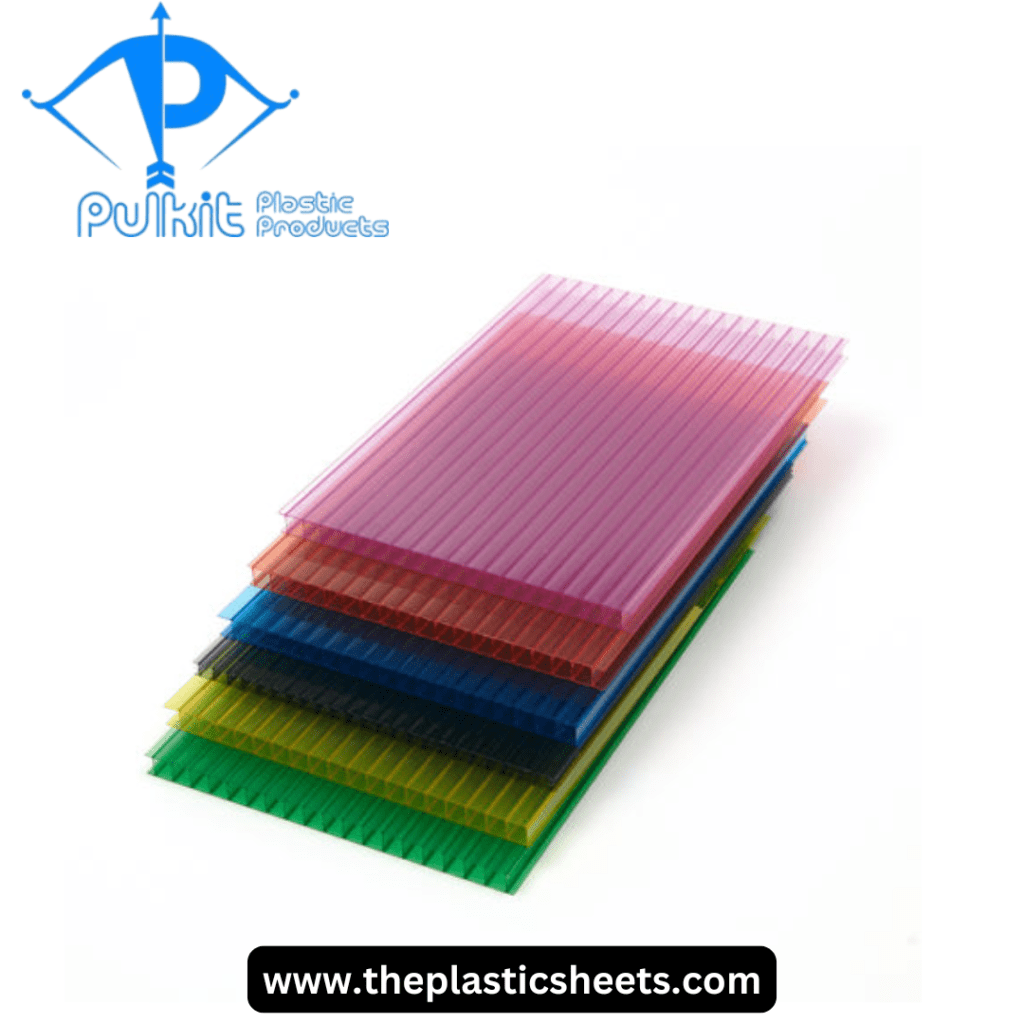

PP corrugated sheets stand at the forefront of the packaging industry, offering unparalleled versatility, durability, and sustainability. Crafted from high-quality polypropylene (PP), this sheet boasts impressive rigidity, resistance to impact, and an exceptional weight-to-strength ratio. With an array of uses spanning industrial, commercial, and residential sectors, understanding the production process, diverse applications, and benefits of PP corrugated sheets is crucial. This Pulkit Plastic Products delves into the key aspects of this innovative material, exploring the latest manufacturing techniques, industrial applications, and potential benefits of partnering with a reliable fluted plastic sheets supplier. We will also explore how to connect with reputable polypropylene corrugated sheets manufacturers who cater to a diverse range of industries and end-users.

Production Process: The Genesis of High-Quality PP Corrugated Sheets

The production process of PP corrugated sheets involves a multi-stage procedure that combines cutting-edge machinery and precision techniques. The process commences with high-quality polypropylene (PP) pellets, which are extruded and formed into a sheet. This sheet is then passed through a series of rollers, where it undergoes calandering, creasing, and shaping, resulting in a smooth, flat surface. The corrugated design is achieved by passing the sheet through a corrugator, which creates the distinctive flute pattern. The sheet is then cut to desired dimensions and finished with an optional coating for added durability and protection.

Applications: Unlocking the Multifaceted Potential of PP Corrugated Sheets

The versatility of PP corrugated sheets has led to their widespread adoption across various industries. From protective packaging for industrial and commercial goods to construction and DIY projects, the sheets provide unmatched durability and versatility. The construction industry relies on PP corrugated sheets for roofing and wall cladding, thanks to their weather-resistance and fire-rated properties. Additionally, the sheets are used in a variety of packaging applications, including shipping containers, crates, and even furniture and shelving. Their ability to withstand harsh environments and resist moisture makes them an ideal choice for outdoor installations, such as walkways and patios.

Key Benefits: Unlocking the Full Potential of PP Corrugated Sheets

The Polypropylene corrugated sheets offer numerous benefits that set them apart from traditional materials. Their high rigidity and strength-to-weight ratio make them ideal for load-bearing applications. The sheets provide exceptional resistance to impact, chemicals, and UV light, reducing the need for additional coatings or treatments. The lightweight nature of PP corrugated sheets makes them easier to handle and transport, reducing logistical costs. Moreover, the sheets are non-toxic, non-abrasive, and can be easily recycled, making them an eco-friendly alternative to traditional materials.

Environmental Considerations: Sustainability in the Production and Use of PP Corrugated Sheets

Sustainability plays a significant role in the production and use of PP corrugated sheets. While traditional corrugated cardboard has seen widespread use, it has environmental drawbacks. In contrast, PP corrugated sheets are made from recycled content, reducing waste and the environmental impact of manufacturing. Their long lifespan and recyclability make them an eco-friendly choice. Furthermore, the sheets can be produced with minimal energy and water consumption, making them a more sustainable option for industrial and commercial applications.

Choosing the Right Fluted Plastic Sheets Supplier: Ensuring Quality and Reliability

Partnering with a reputable fluted plastic sheets supplier is crucial to ensure that your needs are met. Consider a supplier who can offer a wide range of dimensions, thicknesses, and coatings to cater to different applications. Look for a supplier who prioritizes quality control, ensuring consistent standards across all products. Evaluate their environmental policies and sustainable practices to align with your business goals. Assess their customer service and after-sales support to guarantee timely assistance and guidance.

Customization Options: Tailoring PP Corrugated Sheets to Your Specific Needs

The PP corrugated sheets can be customized to meet specific requirements. You can choose from various flute patterns, dimensions, and thicknesses to suit different applications. Coatings can be added for added durability, resistance to chemicals, or to enhance UV protection. The sheets can also be finished with various profiles, such as corrugated, flat, or creped, to suit unique needs. Customization options enable you to optimize your use of PP corrugated sheets, reducing waste and enhancing efficiency.

Safety Considerations: Ensuring Proper Handling and Usage of PP Corrugated Sheets

When handling and using PP corrugated sheets, safety must be a top priority. Wear protective gear, such as gloves, goggles, and a dust mask, to prevent injury from sharp edges, dust, or chemicals. Ensure the sheets are properly secured to prevent accidents caused by falls or flying debris. When using the sheets for load-bearing applications, always follow manufacturer guidelines to avoid overloading and structural damage. Regularly inspect the sheets for signs of damage or wear, replacing them promptly to prevent accidents and maintain efficiency.

Conclusion: Unlocking the Full Potential of PP Corrugated Sheets

The Fluted plastic sheets have emerged as a top choice for various industries, offering unparalleled versatility, durability, and sustainability. Their production process has evolved to incorporate cutting-edge machinery and techniques, producing high-quality sheets that cater to diverse applications. By understanding the benefits, applications, and customization options of PP corrugated sheets, you can unlock their full potential and optimize your use of this innovative material.

Frequently Asked Questions

What is the primary benefit of using PP corrugated sheets over traditional materials?

PP corrugated sheets offer superior resistance to impact, UV light, and chemicals, reducing the need for additional coatings or treatments.

How do I determine which PP corrugated sheet profile is best suited for my application?

Evaluate the specific requirements of your application, including load-bearing capacity, chemical resistance, and UV protection, to determine the optimal flute pattern, thickness, and finish.

What are the environmental benefits of using PP corrugated sheets?

PP corrugated sheets are made from recycled content, reducing waste and the environmental impact of manufacturing. They can be produced with minimal energy and water consumption and are recyclable.

Can PP corrugated sheets be customized to meet specific needs?

Yes, PP corrugated sheets can be customized to meet specific requirements, including dimensions, thicknesses, coatings, and profiles.