Walk through any major city, and you are surrounded by glass. From towering skyscrapers reflecting the clouds to modern storefronts offering a glimpse into high-end retail, the glass facade is a staple of contemporary architecture. It represents transparency, modernity, and technological advancement. But behind every seamless curtain wall and every perfectly fitted window lies a complex web of engineering and documentation.

The gap between an architect’s artistic vision and the physical installation of glass panels is bridged by one critical element: glazing shop drawings.

These documents are far more than simple sketches. They serve as the instruction manual for the building’s exterior skin. Without them, the precise geometry required for modern facades would be impossible to achieve. For construction teams, understanding the role and importance of these drawings is the difference between a profitable project and a logistical nightmare.

What Are Glazing Shop Drawings?

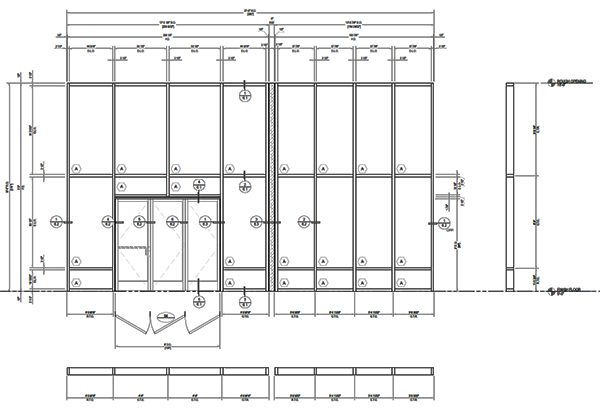

To understand their value, we must first define what they are. Architectural drawings provide the overall design intent—the “look and feel” of the building. Glazing shop drawings, however, are the technical translation of that intent into fabrication and installation instructions. Glazing shop drawings services play a crucial role in bridging this gap.

Created by the glazing contractor or a specialized drafting firm, these drawings detail every component of the glass and metal systems. They include:

- Dimensions: Exact measurements for glass panes, aluminum frames, and clearance gaps.

- Section Views: Detailed cuts showing how the system anchors to the building structure.

- Component Lists: Specifics on gaskets, sealants, bolts, and brackets.

- Material Specifications: Information on glass types (tempered, laminated, insulated) and finishes.

The Critical Role of Shop Drawings in Construction

The complexity of modern building envelopes leaves zero room for improvisation on the job site. Glazing shop drawings function as the central nervous system of the facade installation process. Here is why they are indispensable.

Accuracy and Precision

Glass is an unforgiving material. Unlike wood or drywall, which can be trimmed or adjusted on-site, tempered glass cannot be cut once it is manufactured. If a pane arrives on site and is half an inch too wide, it is useless. It must be reordered, leading to significant delays and wasted capital.

Shop drawings ensure that every dimension is verified against the actual field conditions before fabrication begins. They account for tolerances and building movements, ensuring that the manufactured components fit together perfectly like a complex puzzle.

Communication and Coordination

A construction site is a hub of distinct trades working in close proximity. The concrete team, the steel erectors, and the interior finishers all need to know what the glazing team is doing.

Shop drawings serve as the universal language between these groups. They allow the architect to review technical details to ensure the aesthetic vision is maintained. Simultaneously, they tell the general contractor where blocking is needed to support the window frames. This coordination minimizes clashes and conflicts, ensuring the facade integrates smoothly with the building’s structure and mechanical systems.

Quality Control

The review process for shop drawings is rigorous. It acts as a virtual “dry run” of the installation. During this phase, architects, engineers, and contractors scrutinize the details to identify potential issues.

Does the waterproofing detail actually work? Is there a thermal bridge that will cause condensation issues? Are the anchors accessible for the installers? By answering these questions on paper (or screen) rather than on the scaffolding, the team maintains high standards of quality control. It allows for problem-solving when the cost of change is low, rather than finding defects during construction when the cost of change is astronomical.

Regulatory Compliance

Modern facades must withstand immense environmental pressures, from hurricane-force winds to seismic activity. Shop drawings are often accompanied by structural calculations stamped by a licensed engineer.

These documents prove to local building authorities that the proposed system meets all relevant safety codes and performance standards. They demonstrate that the glass is thick enough, the anchors are strong enough, and the system provides the necessary fire or thermal resistance. Without approved shop drawings, the project cannot legally proceed.

Cost Savings

It might seem counterintuitive that spending money on detailed drafting saves money overall, but the return on investment is substantial. The cost of a drafting error is merely the time it takes to revise a CAD file. The cost of a construction error involves wasted materials, labor for removal and re-installation, schedule delays, and potential penalties.

By investing in high-quality glazing shop drawings, contractors insulate themselves from financial risk. They ensure that materials are ordered correctly the first time and that labor is used efficiently.

Best Practices for Glazing Shop Drawings

Creating these documents is a specialized skill that sits at the intersection of architecture, engineering, and manufacturing. To maximize their value, industry professionals should adhere to several best practices.

Leverage Technology

Modern drafting is moving beyond simple 2D lines. The integration of Building Information Modeling (BIM) allows drafters to create 3D models of the glazing systems. This facilitates clash detection and allows for more complex geometries to be visualized and solved.

Detailed Review Cycles

The approval process should never be a rubber stamp. Sufficient time must be allocated in the construction schedule for the architect and engineer to review the shop drawings thoroughly. Rushing this stage almost guarantees errors down the line.

Utilize Specialized Expertise

Because of the niche knowledge required—understanding aluminum extrusion profiles, sealant compatibility, and thermal expansion—general drafting teams often struggle with facade specifics. This is where partnering with dedicated experts becomes a strategic advantage.

Firms like Archdraw Outsourcing specialize in this exact domain. By utilizing a dedicated team that focuses solely on architectural and structural drafting, contractors can ensure their shop drawings are not only accurate but also adhere to the latest industry standards. Outsourcing this function allows glazing contractors to focus on fabrication and installation while trusting the technical documentation to specialists who understand the nuances of curtain walls, storefronts, and skylights.

The Foundation of a Successful Facade

A building’s facade is its first impression and its primary defense against the elements. While the shimmering glass captures the public’s attention, the success of that facade is determined weeks or months earlier, on the computer screens of skilled drafters.

Glazing shop drawings provide the roadmap for safety, aesthetics, and financial success. They transform abstract concepts into tangible reality, ensuring that the intricate dance of construction proceeds without a misstep. For any project aiming for precision and durability, prioritizing high-quality shop drawings is not just a recommendation; it is a necessity.