In today’s fast-paced world of technology, the demand for high-quality, efficient, and reliable electronic components is growing. Among these components, printed circuit boards (PCBs) play a crucial role in ensuring that devices from smartphones to computers and medical equipment function correctly. Choosing the right PCB supplier is a decision that impacts both product quality and cost-effectiveness. As technology continues to advance, the debate over whether to work with a local or global PCB supplier is one that many businesses face. In this article, we’ll explore both options to help you decide which one best suits your needs.

Understanding the Role of a Printed Circuit Board Supplier

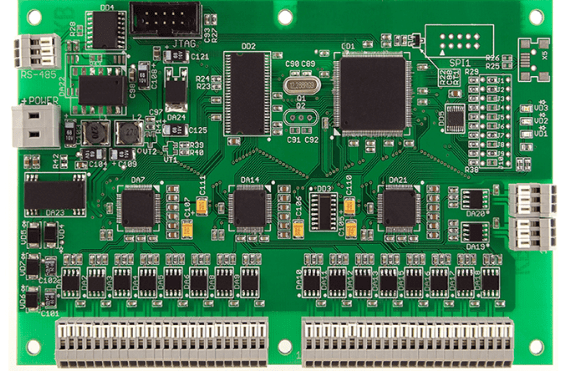

Before diving into the local vs. global debate, it’s important to understand the role a printed circuit board supplier plays. A PCB is a foundational component in any electronic device, providing the physical platform for electrical components such as resistors, capacitors, and microchips to be mounted and connected. Printed circuit board suppliers are responsible for producing these boards according to precise specifications, ensuring that they meet industry standards and are compatible with the device they will be part of.

The reliability, functionality, and durability of the PCB directly affect the performance and safety of the final product. Therefore, selecting the right supplier is crucial for ensuring the success of a product, whether it’s an everyday consumer gadget or a life-saving medical device.

Local PCB Suppliers: The Advantages

Opting for a local PCB supplier can bring several benefits to the table, especially for businesses looking for quick turnaround times, easy communication, and strong support networks.

Proximity and Faster Lead Times

One of the key advantages of choosing a local PCB supplier is reduced lead times. With suppliers located closer to your manufacturing facility, shipping times are shortened, and delays are less likely to occur. If a critical error is discovered in the PCB design or production process, it’s easier to work with a local supplier to resolve the issue promptly. This is especially important in industries where time-to-market is critical.

Easier Communication and Collaboration

When working with a local supplier, communication is generally more straightforward. Time zone differences are less of a challenge, and any issues that arise can be dealt with more efficiently through face-to-face meetings or direct phone calls. This makes it easier for engineers and product designers to collaborate on custom PCB designs and modifications.

Support for Local Economies

Choosing a local supplier supports the regional economy by creating jobs and promoting business growth within your own country or region. It fosters a sense of community and partnership and can also improve a company’s reputation as a responsible, locally invested business. For those concerned with the environmental impact of global supply chains, sourcing locally can sometimes result in a smaller carbon footprint due to reduced transportation requirements.

Quality Control

Local suppliers are often able to offer more direct oversight of the manufacturing process. Businesses can perform on-site inspections, ensuring that the PCB quality aligns with the required standards. Additionally, many local PCB suppliers pride themselves on personalized service, offering customized solutions that can meet specific technical and quality requirements.

Global PCB Suppliers: The Benefits

On the other hand, there are compelling reasons why many businesses choose global PCB suppliers. In fact, many of the most well-known and successful electronics manufacturers rely on international suppliers to meet their high-volume production needs. Here are some of the primary advantages of working with a global PCB supplier:

Lower Costs

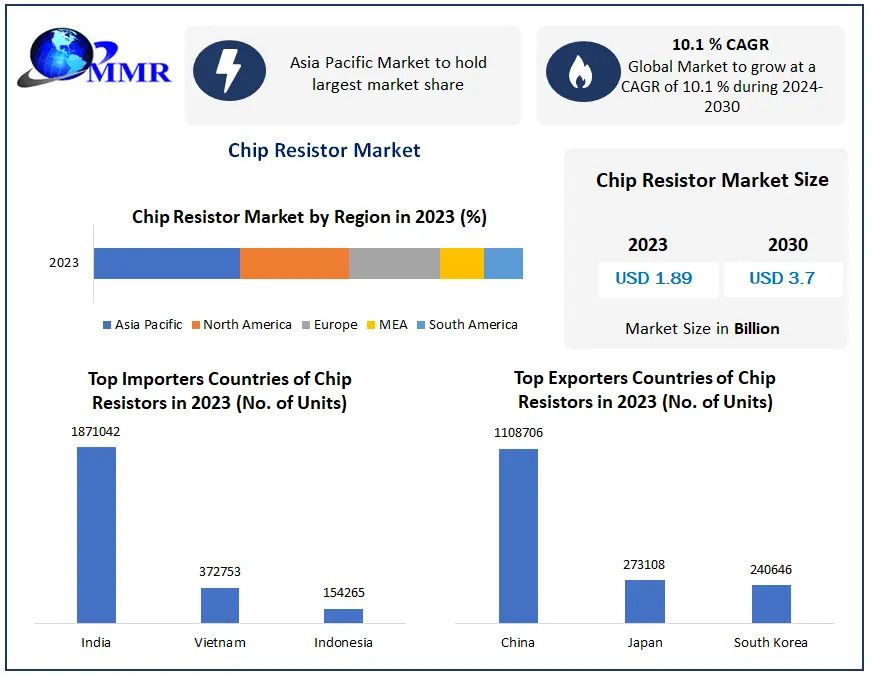

Perhaps the most significant advantage of global suppliers is cost. Many international PCB suppliers, particularly those in regions like China, Taiwan, and South Korea, can produce PCBs at a fraction of the cost compared to local suppliers. This cost reduction is due to various factors, including lower labor costs, economies of scale, and the ability to source raw materials at cheaper prices.

For businesses that require large quantities of PCBs, working with a global supplier can be a more cost-effective solution, especially when production volumes are high. This is particularly true for consumer electronics companies where profit margins are slim, and cost efficiency is key.

Access to Advanced Technology

Global suppliers often have access to more advanced manufacturing technologies and equipment. These suppliers are capable of producing high-precision PCBs with complex designs, such as multi-layered boards or flexible PCBs, which might be challenging for smaller, local suppliers to produce. If your project requires cutting-edge PCB designs, a global supplier might be able to offer more specialized solutions.

Additionally, larger global suppliers typically have a wider range of capabilities, including offering both low and high-volume production runs, which can provide flexibility depending on your business needs.

Larger Capacity for High-Volume Orders

For businesses that need to scale their production quickly, global PCB suppliers often offer greater production capacity. These suppliers can meet large and ongoing orders due to their well-established operations, automation, and extensive supply chains. They are often better equipped to handle high-volume, continuous production runs, which is a key benefit for electronics manufacturers looking to meet rising consumer demand.

Global Reach and Diverse Expertise

Working with a global PCB supplier provides access to a diverse talent pool and a broader range of expertise. These suppliers often employ top engineers, designers, and technicians who are experts in different aspects of PCB manufacturing. By partnering with such suppliers, businesses can tap into innovative ideas and industry-leading practices that may not be available locally.

The Trade-Offs: Local vs. Global PCB Suppliers

While both local and global PCB suppliers offer unique advantages, the trade-offs should be considered carefully. The decision often depends on the specific needs and constraints of the business in question. Here’s a quick summary of the factors to weigh:

- Lead Time vs. Cost: Local suppliers may offer faster lead times but can be more expensive. Global suppliers may offer lower costs but come with longer shipping times and potential language barriers.

- Customization vs. Volume: Local suppliers can provide more personalized service and customized PCB designs, whereas global suppliers excel at mass production with higher output and less customization.

- Quality Control vs. Advanced Technology: While local suppliers can offer closer monitoring of quality and easier communication, global suppliers tend to have access to advanced manufacturing technologies and can handle more complex projects.

Conclusion:

Choosing between a local and global printed circuit board supplier requires careful consideration of factors such as cost, lead time, volume, and customization needs. By weighing the advantages and disadvantages of each option, you can make an informed decision that aligns with your business objectives.

To find out more about local and global PCB suppliers, it’s a good idea to check over here for comparison charts and reviews of various suppliers. Whether you opt for a local or global supplier, understanding the nuances of each option will help you get the best value, quality, and service for your projects. For businesses ready to expand their supply chain globally, go right here for expert advice and industry insights on selecting a reliable, high-quality PCB supplier that meets your specific needs.