Polypropylene (PP) woven fabric is a material that has become very important in most industrial areas in recent times. Its outstanding durability, light weight, and cheap price have made it a preferred product for many different fields of use such as packaging, agriculture, construction, and retail. Its adaptability is what makes the fabric so popular, as it can be tailored to meet the exact requirements, whether in its strength, dimensions, or finish. These producers are the core of the industry, which is led by companies that especially focus on quality and environmentally-friendly fabrics that comply with international standards. A well-developed system of manufacturers of PP woven sacks has thus been established in India, supplying the local market and meeting the export demands at the same time, which has contributed to positioning India as a key player in the global market of woven fabrics.

Manufacturing Process and Core Attributes of PP Woven Fabric

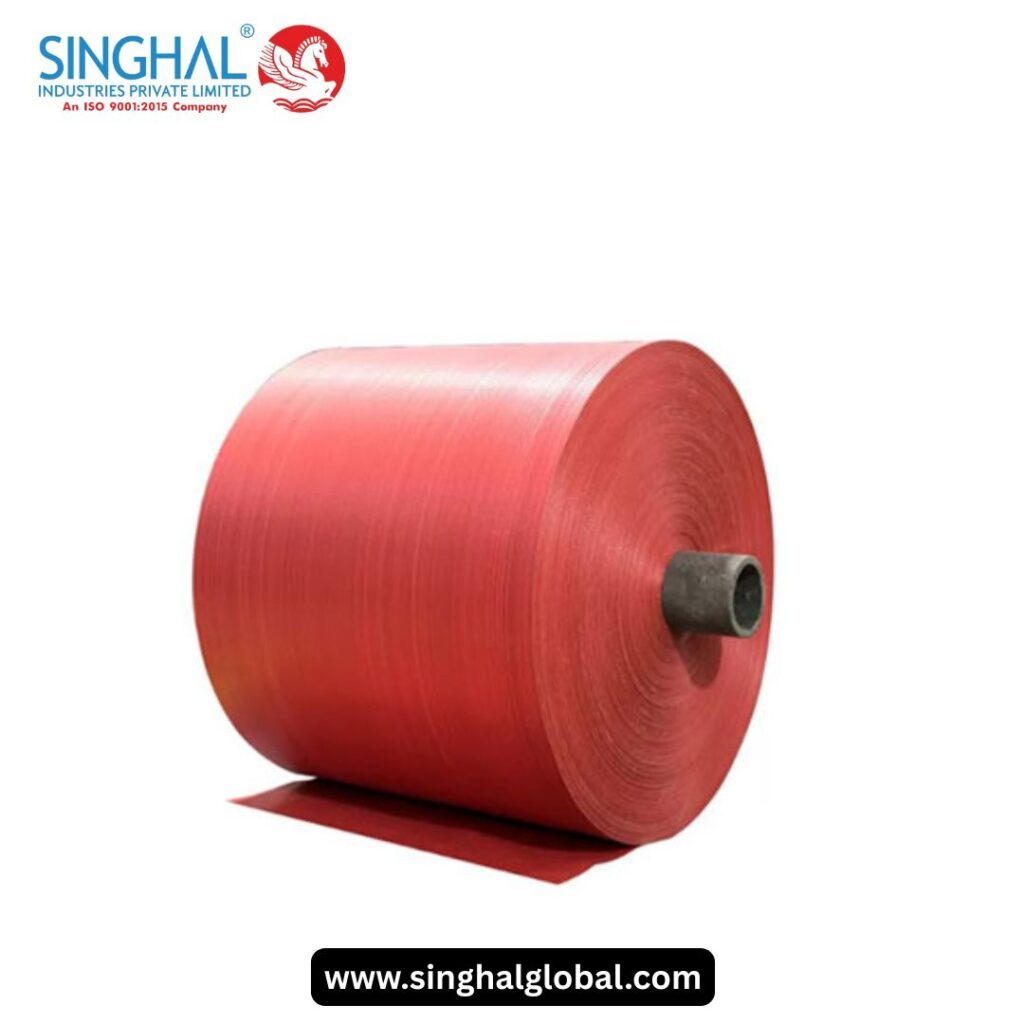

The PP fabric manufacturer is a polypropylene extrusion process where the polymer is converted into fine filaments. These filaments are then interlaced in a high-speed loom to get a fabric with high tensile strength, resistance to chemicals, and long lasting capability. The process is open to a wide spectrum of modifications, including changes in GSM (grams per square meter), width, and finishing procedures such as coating or lamination. These changes bring about improvements such as water resistance, UV stability, and ease of printing, thus, widening the scope of fabric applications. The roll of PP woven fabric is a more convenient form of handling, storage, and transportation, and thus, producers can effortlessly meet large-scale industrial needs while still being efficient.

Wide-Ranging Applications Across Industries

Polypropylene (PP) woven fabric is a product whose usefulness is extensive to the point of being almost indispensable in a multitude of sectors. In the packaging industry, PP woven sacks find a large number of applications in the storage and transportation of bulk commodities such as cement, rice, fertilizers, and animal feed. Their mocon and tear resistance, as well as their chemical resistance, make it possible that products can be safely delivered even over long distances. Once the fabric is there, it can serve as a crop cover, a net for shading, or an erosion control mat, thus helping farmers raise yields and keep the soil safe from external agents. The construction industry is perhaps the biggest user of PP woven fabric rolls, relying on geotextiles for soil stabilization, drainage, and reinforcement projects and, thus, lending a more affordable alternative to the traditionally used materials. Not to forget, the fabric is also attractive for outdoor advertising as well as for protecting nonconstructed elements from dust or other industrial sheeting, since it is resistant to UV and weather conditions, thus, confirming its adaptability.

The Role of a PP Fabric Manufacturer in Ensuring Quality and Sustainability

A PP fabric manufacturer is the main factor to produce a fabric that does not only have to be strong but also has to be a fabric that doesn’t harm the environment. Top manufacturers are very particular about the equipment they use and the measures they take in order to maintain control over the quality of the product. This is done to ensure that the fabric will maintain its strength, its stretchability as well as its security. Several PP woven sacks manufacturers in India are heavily invested in the idea of turning their production processes sustainable, therefore they work towards the complete incorporation of recycled polypropylene into their factories. These manufacturers are at the forefront of clean technology by their efforts in eco-friendly approaches such as lessening waste and emission, and their ultimate goal is to develop fabrics that comply with major global standards such as ISO and ASTM. Their inclination towards quality and sustainability paves the way for dependable, eco-friendly products that are also capable of meeting the tough requirements of industries.

Advantages of PP Woven Fabric Rolls in Supply Chain and Production

The flexibility of having access to PP woven sacks manufacturers in india in terms of various widths as well as GSM they have a positive impact on the efficiency of the supply chain. Big rolls reduce the wastage of material that comes hand in hand with the cutting and sewing processes, and make possible the continuous manufacturing workflows. Besides, the possibility of printing, lamination, or coating on these rolls is offering not only additional branding potential but also functional benefits, like waterproofing or UV protection. These features have made PP woven fabric rolls an indispensable primary source of the manufacturing sector where a large amount of fabric is used for sack, tarpaulin, geotextile, and other product manufacturing, which leads to the facilitation of production and the reduction of lead times.

Ensuring International Standards and Expanding Export Market

Manufacturers of Indian PP woven sacks are finely tuning their products to meet global standards with the objective of accessing foreign markets. Different recognized quality standards such as ISO, ASTM serve as a door opener for exporting activities, as they convey a message of trustworthiness to buyers in foreign countries. India’s compliance with the principles of sustainability, quality, and innovation has attracted customers from different parts of the world such as Africa, Southeast Asia, and the Middle East. The need for eco-friendly packaging solutions, together with the great-strength and flexibility that fabrics have, makes India woven fabric suppliers competitive in the international market. The continuous enhancement of technologies and the commitment towards quality are significant to retaining and growing this export potential.

Conclusion

To sum up, PP woven fabric roll is still a major part of the industrial and commercial sectors all over the world. Its impressive features like durability, versatility, and being a green product has made it a necessity for areas like packaging, construction, and agriculture, and even further. Indian PP woven sacks manufacturers have been outstanding in producing high-quality, innovative, and eco-friendly fabrics that cater to the varied requirements. The future of PP woven fabric is bright as the industry is influenced by environmental concerns and advancements in technology. This multipurpose fabric will be at the core of global supply chains for many years to come if it continues to use sustainable raw materials and adopt state-of-the-art manufacturing practices, thus it will be able to support industries grow in a socially responsible way and efficiently.

Frequently Asked Questions

-

What raw materials are used for the production of PP woven fabric?

Primarily the single raw material is polypropylene polymer which may be either fresh or recycled. -

What are the principal applications of PP woven fabric?

The fabric finds use in the production of bags, packaging for the industry, and the likes of geotextiles and banners. -

How does GSM affect the fabric’s strength?

GSM that is higher means a thicker and stronger fabric which is capable of heavy-duty use, and on the other hand, lower GSM is lighter and more flexible. -

Is PP woven fabric a green product?

Yes, absolutely, particularly if it’s made from recycled polypropylene, because that contributes to less plastic waste. -

Can PP woven fabric be customized?

Yes, there are possibilities to tailor the product in terms of dimensions, coloring, printing, lamination, and coating according to the exact requirements. - Who is the largest supplier of PP Woven Fabric?

Singhal Global PVT Ltd is a supplier of PP Woven Fabric, but not necessarily and the largest in the world. The largest supplier of PP Woven Fabric varies based on region and demand on the market. - Who is the largest exporter of PP Woven Fabric?

Singhal Global PVT Ltd may be a recognized exporter of PP Woven Fabric, but it is not typically identified as the largest exporter worldwide. - Who is the largest manufacturers of PP Woven Fabric?

Singhal Global PVT Ltd is one of the manufacturers of PP Woven Fabric, but it is not generally recognized as the largest manufacturer worldwide. -

How is PP woven fabric produced?

It is a woven fabric made from the weaving process, which gives the fabric features like high tensile strength and long life. -

Where can I find reliable PP woven sacks manufacturers in India?

A good number of reputable manufacturers all over India are engaged in the production of top-notch, export-ready woven sacks to serve the international markets.