A Strong Packaging Option for Multiple Industries

In today’s industrial and agricultural sectors, packaging solutions must be dependable, economical, and user adaptable. Their remarkably good strength-to-weight ratio, ability to withstand weather and durability, along with their cost effectiveness, have been significant factors in their success. PP woven bags are made by weaving strips of polypropylene into a serviceable fabric that is then cut and stitched to form a bag. This allows for a wide variety for bag usage ranging from grains, sugar, cement, fertilizers, and a wide variety of other dry bulk products Polypropylene PP Bags have a consistent quality for durability that attracts consumer use both for domestic and export purposes.

Various Applications Across Key Market Segments

The versatility of flexible packaging is one of the main drivers of its widespread usage. Flexible bags are used in the construction industry to transport products like cement and sand. Because of their ability to resist tearing and puncturing, flexible bags can help ensure the safe transportation of goods over long distances. Flexible bags are also used in retail and wholesale situations for packaging items that need both strength and flexibility. Because they can be stacked, stored, and reused, flexible bags are feasible for many packaging situations.

Advantages That Contribute to Their Growing Demand

The increasing demand for this type of packaging can be traced to its many advantages. The bags are light and strong, which means lower shipping costs, with no loss of strength. They are water resistant and will afford some protection to sensitive items that are stored or cross-shipped. The surface of the bags can be laminated or printed which allows for custom branding and labeling. Whether companies need unbranded storage or unbranded printed retail bags, this packaging material is well adapted to a wide variety of business needs. This type of custom branding also allows for added personal touches for companies. This enables companies to reinforce their own branding while keeping their product safe.

Manufacturing Quality and Regional Capabilities

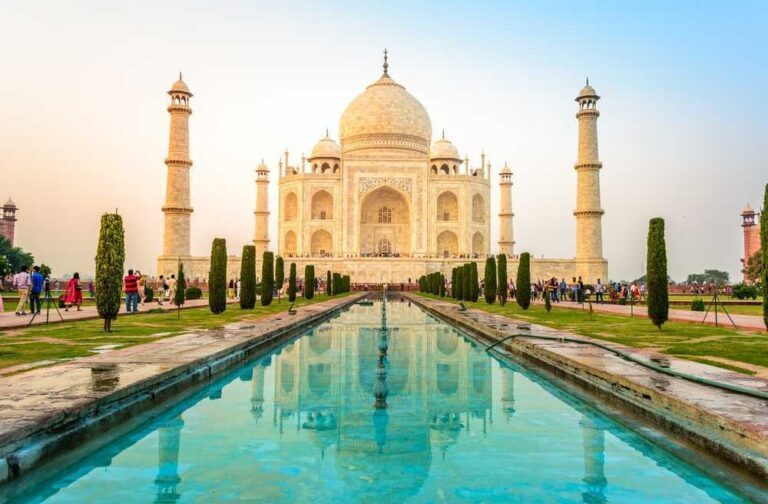

India has established a place for itself in the world as a top supplier of high-quality packaging based on polypropylene. One of the most prestigious industries leading the way is Mumbai, where manufacturers are known for producing innovative, custom designed packaging solutions. A noted PP Plastic Bag Manufacturer in Mumbai is likely to produce a catalogue of products for the many industries it serves. In most cases, the manufacturer utilizes automated weaving, cutting, printing, and stitching which allows it to maintain consistency in quality and delivery. The manufacturer, like many others throughout the world, is adopting global standards for its packaging fulfilling the expectations of its local and international buyers.

Specialty Products for Industry-Specific Needs

Manufacturers are coming out with different specialty bag options to satisfy many of the specific needs related to a given industry. Examples include food-grade products made in hygienic conditions to pack consumable goods, UV resistant options designed for outdoor uses for agriculture, construction etc. Leading manufacturers are also packaging pp bags for sale with liners, valve tops or gussets to meet the needs for products needing special containment or handling. With product choices, in a wide range of options, customers will find exactly what they are looking for.

Environmental Considerations and Reusability Benefits

One of the great benefits of these bags is their reusability. Woven polypropylene is distinct in that it can be reused several times, unlike single-use plastics, which further improves sustainability efforts in packaging. After use, bags can be collected, wiped out, and reused while remaining intact and the vendor can reuse without having to add to the waste stream. Many businesses are choosing this over disposable packaging, because it is the environmentally sustainable thing to do, and in turn helps businesses save money (reducing operational costs) as well as environmental impacts. The materials used to produce are also recyclable, reducing waste and preserving materials.

Future Prospects in the Packaging Industry

The future for woven polypropylene options seems bright with advancements in polymer technology and an increasing requirement for durable, eco-friendly packaging. The expansion of international trade and logistics means higher demand for packaging that can provide protection to the products during shipment. Businesses that invest in high quality, reusable packaging will enjoy both cost savings and greater product protection. These plastic materials can then be recycled and reused at the end of their life and provide an environmental benefit for the future. As awareness grows, and more standards for packaging emerge, bags like these will continue to grow as a vital part to global supply chains across a wide range of industries.

Conclusion

The PP woven bag category will remain a reliable and economical option for a variety of packaging applications. PP woven bags have many applications, from agricultural uses to industrial logistics, and these bags have been used in thousands of applications. Producers from places like Mumbai are exposing the worth of these types of products by producing quality PP woven bags manufactured to achieve international standards PP Polythene Bags Manufacturer offer various benefits, such as reusability, customization, and strength, at a good balance of durability and sustainability for an ideal packaging method of operations.

Frequently Asked Questions

What materials are used in these bags?

These bags are made from woven polypropylene, a thermoplastic polymer that is strong, flexible, and resistant to environmental stress.

Can these bags be printed with custom branding?

Yes many manufacturers offer custom printing services for these bags allowing businesses to show their logo, product information or branding onto the packaging.