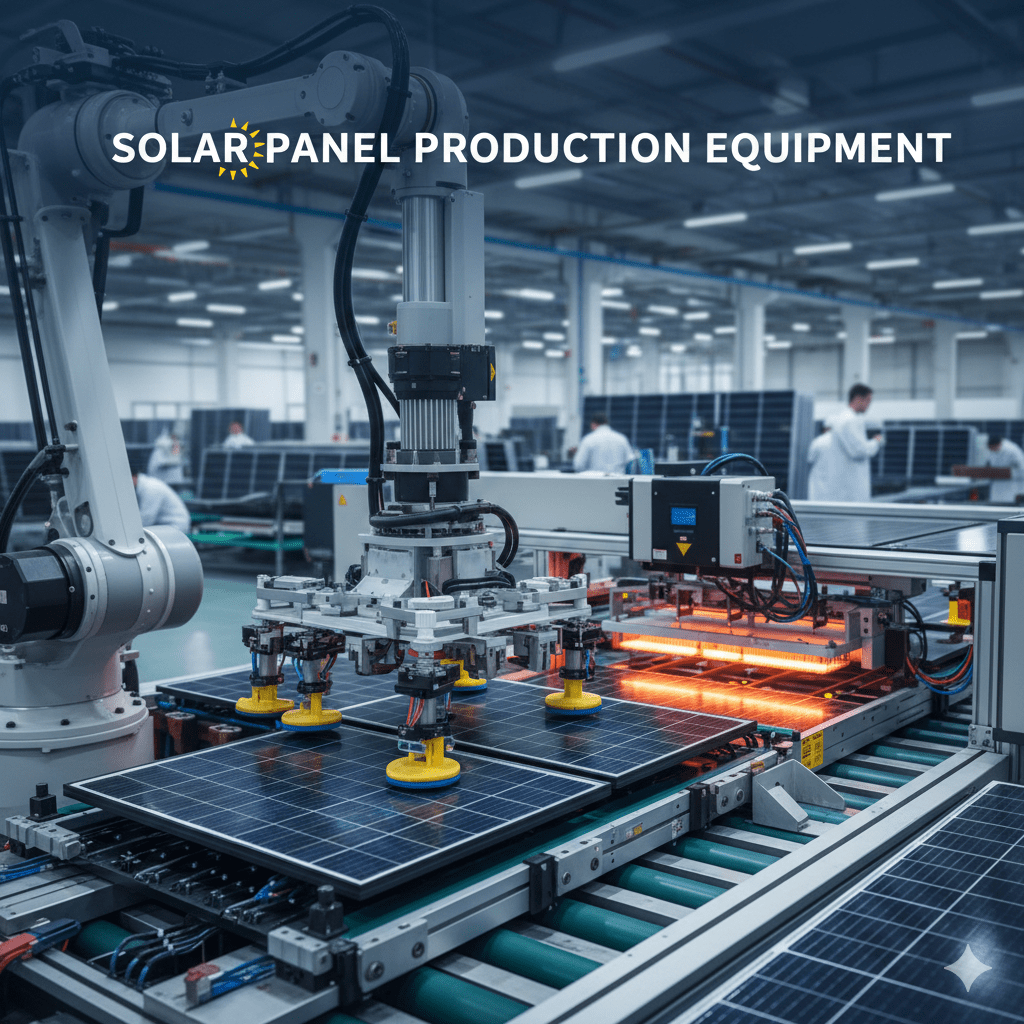

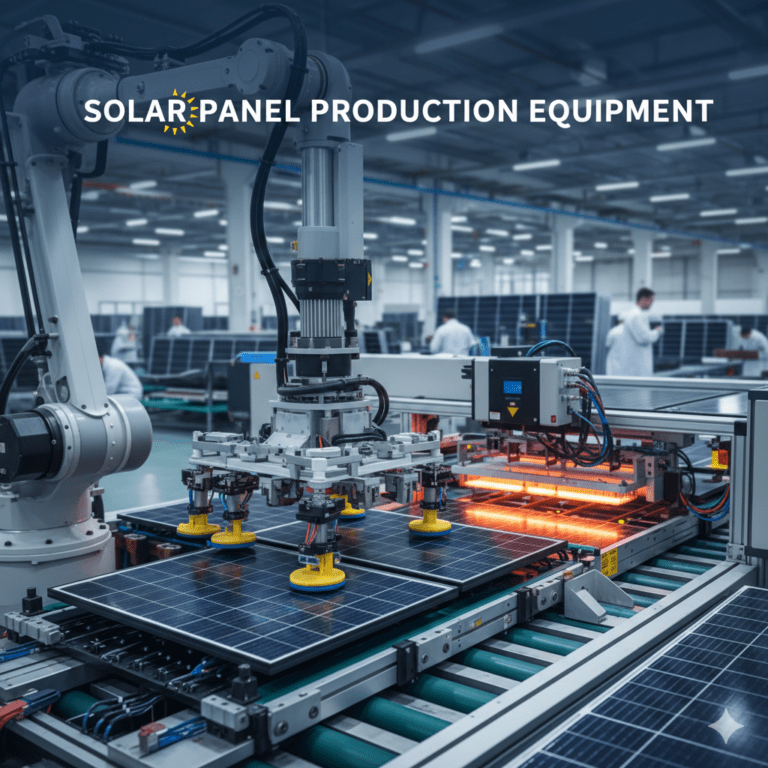

The revolution of renewable energy is considerably reshaping how the world produces power, & at the core of this transformation lies advanced solar module production machinery & high-performance solar panel production equipment. These particular technologies forms the backbone of modern solar manufacturing. It enable companies to produce the most efficient, reliable, & durable solar panels at scale. As the demand for clean energy is witnessed to surge globally to a large extent, the overall significance of precision-driven manufacturing has never been greater.

Building the Base for an Efficient Solar Manufacturing

Every solar panel of highest quality begins its journey on a well-engineered and optimally efficient production floor. Solar module production machinery brings together accuracy, automation, & consistency across every stage of the process. It starts from cell stringing & lamination to framing & final inspection. Each step is well-designed to minimize the levels of errors, reduce waste, & maximize output.

Meanwhile, the advanced solar panel production equipment always largely ensures that the precision alignment tools, as well as the controlled processes of lamination work together in order to deliver the most uniform panels that meet the strictest standards of quality. This harmony between machinery & process is what enables manufacturers to scale efficiently that too without sacrificing the aspect of quality.

Driving the Best Quality through the Advanced Technology

In the field of solar manufacturing, quality is indeed non-negotiable. Panels are being expected to perform reliably for several decades together, often under the most extreme environmental conditions. Modern solar module production machinery is well-built in order to maintain the right level of tolerances, ensuring the most consistent cell placement, strong interconnections, as well as durable encapsulation.

The high-end solar panel production equipment also optimally supports the integrated inspection as well as testing at multiple stages. Early detection of the defects prevents the faulty panels from moving forward, saving a lot of your valuable time as well as resources. This particular proactive approach always helps in protecting both manufacturers as well as end users while reinforcing trust in solar technology.

Boosting Productivity & Reducing Costs

One of the biggest advantages of advanced manufacturing systems is efficiency. Automated solar module production machinery significantly reduces manual intervention, speeding up the production cycles & lowering labour costs to a great extent. Faster throughput means manufacturers can respond quickly to market demand while keeping the operational expenses under control.

At the same time, the most optimized solar panel production equipment reduces the material loss & rework. Accurate alignment, precise dosing, & repeatable processes ensure that raw materials are being used effectively, improving the yield rates as well as overall profitability.

Supporting Innovation & Scalability

As solar technology continues to evolve, manufacturing systems must have to adapt at the same time. Modern solar module production machinery is well-designed with flexibility in mind, allowing the manufacturers to upgrade components or adjust the configurations as cell technologies improve. This particular adaptability is highly essential in a fast-changing industry.

The scalable solar panel production equipment also allows the solar panel manufacturers to expand the overall capacity without overhauling their entire setup. This future-ready approach very well supports long-term growth & keeps production facilities highly competitive in an excessively competitive global market.

Building a Highly Sustainable Future of Energy

Efficient manufacturing is considered to be highly instrumental in playing a crucial role in making solar energy accessible & affordable. By leveraging the most advanced solar module production machinery & also reliable solar panel production equipment, manufacturers contribute directly to the global transition toward attaining the most sustainable power.

Every single improvement in the production efficiency lowers the overall costs, increases its adoption to a great extent, & accelerates the shift away from fossil fuels. In this way, manufacturing innovation proves to be a strong catalyst for a significant environmental progress.

Conclusion

The success of the solar industry largely depends on what happens behind the scenes. Precision-engineered solar module production machinery & robust solar panel production equipment form the foundation of high-quality solar panels that power homes, businesses, & all communities throughout the world. As demand for clean energy grows with passing time, smart manufacturing will continue to drive the future of solar energy.