For regulated industries, quality does not end when a product leaves the factory or receives regulatory approval. In fact, that is where some of the most critical quality activities begin. Complaints, adverse events, and real-world usage data provide invaluable insights into product performance, patient safety, and compliance risk. Organizations that fail to connect these signals often struggle with repeat issues, audit findings, and delayed corrective actions.

Why complaint handling is more than a regulatory checkbox

Complaint handling is often viewed narrowly as a compliance obligation. While regulations mandate timely intake, investigation, and reporting, complaints are also one of the most powerful sources of post-market intelligence.

When handled effectively, complaints can:

-

Reveal early signals of product or process issues

-

Highlight gaps in design, labeling, or instructions for use

-

Identify supplier or manufacturing variability

-

Protect patients and customers before issues escalate

The challenge is that many organizations treat complaints as isolated records rather than part of a broader quality ecosystem. Data is captured, closed, and archived, but not fully leveraged.

The missing link between complaints and post-market surveillance

Post-market surveillance is designed to proactively monitor product performance after release, using multiple data sources such as complaints, service records, audits, and regulatory feedback. In practice, these activities are often fragmented.

Common gaps include:

-

Complaint data not linked to risk management or CAPA

-

Audit findings reviewed separately from field performance data

-

Limited trend analysis across products, regions, or time periods

-

Reactive actions taken only after serious incidents or inspections

Without integration, organizations miss patterns that could prevent future issues. Closing the quality loop requires breaking down these silos and treating post-market data as a continuous feedback mechanism.

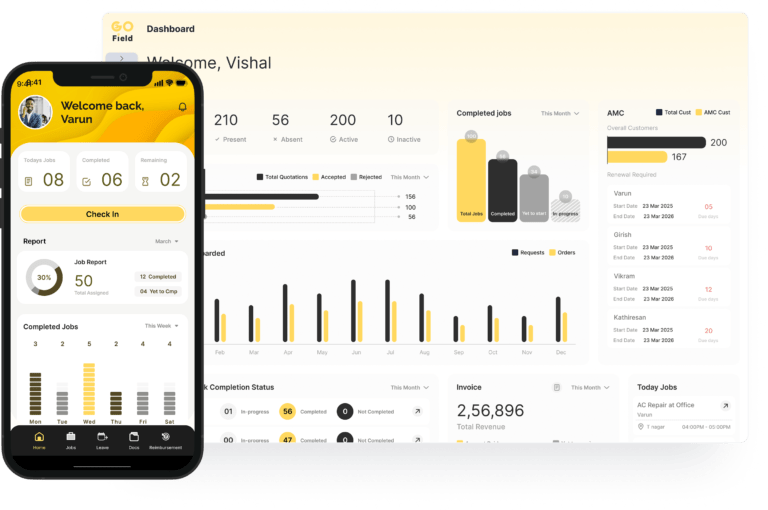

The role of a connected Medical Device QMS

A connected Medical Device QMS provides the foundation for integrating complaint handling and post-market surveillance into a single, traceable process. Instead of managing quality events in isolation, organizations can establish clear relationships between complaints, investigations, risks, and corrective actions.

Key characteristics of a connected approach include:

-

Centralized intake and classification of complaints

-

Consistent investigation workflows aligned with regulatory expectations

-

Automatic linkage to risk files and CAPA when thresholds are met

-

Ongoing trend analysis to support proactive decision-making

This structure enables organizations to demonstrate not only compliance, but control and oversight across the product lifecycle.

Using audits to validate post-market effectiveness

Audits are often associated with internal processes and documentation, but they also play a critical role in validating post-market surveillance effectiveness. Regulators increasingly expect organizations to show how post-market data informs audits and vice versa.

Modern audit management software supports this by:

-

Linking audit findings to complaints and post-market data

-

Highlighting systemic issues rather than isolated nonconformances

-

Tracking corrective actions across multiple quality events

-

Providing evidence of continuous improvement

When audits are connected to real-world performance data, they become a strategic tool rather than a compliance burden.

From reactive fixes to proactive quality improvement

One of the biggest benefits of closing the quality loop is the shift from reactive problem-solving to proactive quality improvement. Instead of waiting for serious complaints or regulatory action, organizations can identify trends early and intervene before issues escalate.

This proactive model typically includes:

-

Regular review of complaint and surveillance trends

-

Defined escalation criteria tied to risk and severity

-

Cross-functional involvement from quality, regulatory, and operations

-

Management review focused on prevention, not just correction

Over time, this approach reduces repeat issues, lowers compliance risk, and improves overall product performance.

Aligning post-market surveillance across industries

While medical devices have well-defined post-market surveillance requirements, similar principles apply across regulated sectors. Organizations operating in life sciences often manage both devices and drugs, making alignment essential.

A unified approach supports:

-

Consistent quality practices across device and pharmaceutical operations

-

Shared visibility into complaints, audits, and CAPAs

-

Easier compliance with global regulatory expectations

For companies operating in both domains, integrating Medical Device QMS practices with a broader Pharmaceutical QMS framework helps ensure consistency, scalability, and regulatory confidence.

Data-driven oversight with modern audit tools

As post-market data volumes grow, manual oversight becomes unsustainable. Modern audit tools enable organizations to manage complexity by providing real-time insights and structured workflows.

These tools help teams:

-

Monitor trends across large product portfolios

-

Prioritize audits based on risk and performance signals

-

Ensure follow-through on corrective and preventive actions

-

Maintain a clear audit trail for regulators

The result is stronger governance and faster response times, even as regulatory expectations evolve.

Culture and accountability in closing the loop

Technology and process integration are essential, but closing the quality loop also depends on organizational culture. Teams must see complaint handling and post-market surveillance as shared responsibilities rather than isolated quality functions.

Successful organizations reinforce this by:

-

Encouraging transparent reporting without fear of blame

-

Training teams to understand how post-market data drives decisions

-

Holding owners accountable for investigation quality and timeliness

-

Engaging leadership in trend review and risk discussions

When accountability is clear and supported by data, quality becomes embedded in everyday operations.

Turning post-market insights into competitive advantage

Organizations that master post-market surveillance gain more than regulatory compliance. They gain insight into how products perform in real-world conditions and how customers interact with them over time.

These insights can:

-

Inform design improvements and innovation

-

Strengthen regulatory submissions and inspections

-

Improve customer trust and brand reputation

-

Reduce long-term quality and compliance costs

Closing the quality loop transforms post-market obligations into a source of strategic value.

For organizations looking to unify complaint handling, post-market surveillance, and audits within a single system, ComplianceQuest provides a scalable, connected platform. By bringing quality, regulatory, and audit processes together, ComplianceQuest helps organizations truly close the quality loop and sustain compliance across the entire product lifecycle.