Electrical losses are a silent drain on performance, safety, and operating costs in control panel systems. For engineers and facility managers working with a control panel wire manufacturer in UAE, understanding how panel wire selection impacts efficiency is essential. Even small inefficiencies in wiring can lead to excessive heat, voltage drops, and higher energy consumption over time. Choosing the right panel wires is not only about meeting electrical requirements—it is about optimizing the entire system for long-term efficiency and reliability.

This article explains how electrical losses occur, the role panel wires play in minimizing them, and the key factors to consider when selecting efficient wiring solutions for control panels.

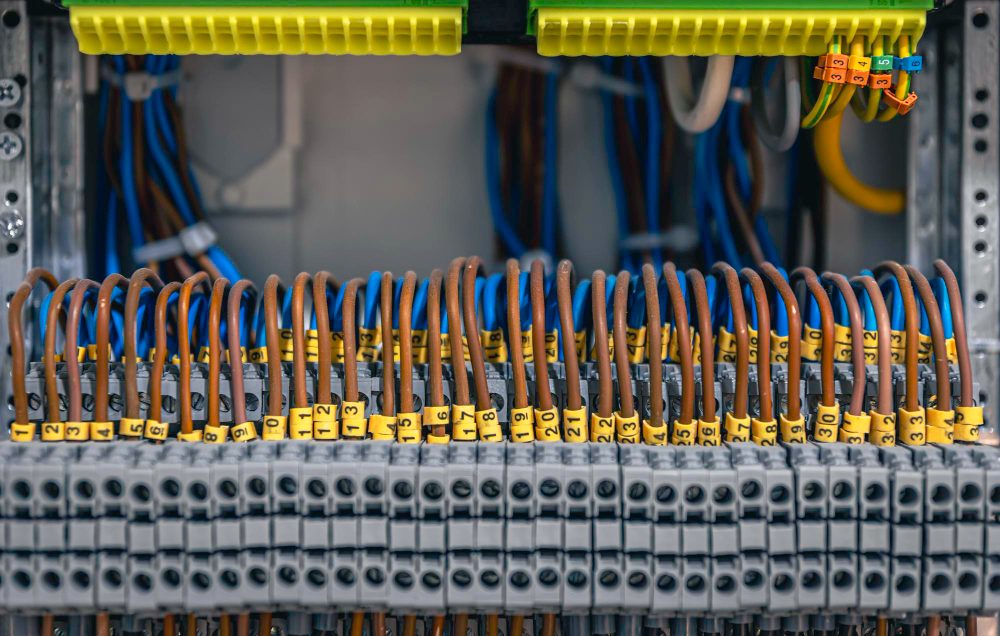

Understanding Electrical Losses in Control Panels

What Are Electrical Losses?

Electrical losses occur when part of the electrical energy is converted into heat instead of being delivered to the load. In control panels, these losses are commonly caused by resistance in conductors, poor connections, and improper wire sizing.

Why Losses Matter

Excessive electrical losses can:

-

Increase energy consumption

-

Cause overheating inside panels

-

Reduce equipment lifespan

-

Lead to unplanned downtime

-

Compromise overall system safety

Reducing these losses starts with selecting the right panel wires.

How Panel Wire Selection Affects Efficiency

Conductor Material and Quality

The conductor is the core pathway for electrical current. High-quality conductors with consistent cross-sections allow electricity to flow smoothly, reducing resistance and heat generation.

Wire Gauge and Current Capacity

Using an undersized wire forces more current through a smaller conductor, increasing resistance and power loss. Correctly sized panel wires ensure that current flows efficiently without excessive heating.

Insulation Performance

Insulation plays a critical role in maintaining conductor integrity. Poor-quality insulation can degrade over time, increasing leakage currents and electrical losses.

Key Factors to Consider When Choosing Efficient Panel Wires

1. Correct Wire Sizing

Proper wire sizing is one of the most effective ways to reduce electrical losses. The conductor must be sized according to:

-

Load current

-

Operating temperature

-

Length of wire run

-

Voltage level

Correct sizing minimizes voltage drop and prevents unnecessary energy dissipation.

2. Low Electrical Resistance

Wires with lower resistance allow current to pass with minimal loss. Selecting panel wires designed for efficient current flow improves overall system performance and reduces internal panel heat.

3. Heat Dissipation Capability

Excess heat inside control panels can reduce efficiency and damage components. Panel wires with suitable insulation and construction help dissipate heat effectively, maintaining stable operating conditions.

4. High-Quality Termination Compatibility

Even the best panel wire can lose efficiency if terminations are poor. Wires that support secure crimping and termination reduce contact resistance, which is a major source of power loss.

The Impact of Voltage Drop on Efficiency

What Is Voltage Drop?

Voltage drop occurs when electrical energy is lost as current travels through a conductor. In control panels, excessive voltage drop can lead to improper equipment operation and reduced efficiency.

How to Minimize Voltage Drop

-

Use appropriate conductor sizes

-

Keep wire runs as short as possible

-

Ensure proper termination and connection quality

-

Avoid unnecessary bends and tight routing

Efficient panel wires help maintain stable voltage levels throughout the system.

Environmental Factors That Influence Electrical Losses

Ambient Temperature

High ambient temperatures, common in many industrial environments, increase conductor resistance. Selecting panel wires rated for higher temperatures helps maintain efficiency even under thermal stress.

Panel Density and Airflow

In compact panels with limited airflow, heat buildup can increase losses. Efficient panel wires with proper insulation reduce internal temperature rise and support better thermal management.

Common Mistakes That Increase Electrical Losses

Using Undersized Wires

Choosing smaller wires to save cost often results in higher resistance, heat buildup, and energy waste.

Ignoring Load Growth

Panels are sometimes designed without accounting for future expansion. Wires that are adequate today may become inefficient as loads increase.

Poor Installation Practices

Loose connections, sharp bends, and overcrowded wiring can significantly increase resistance and power losses.

Benefits of Reducing Electrical Losses Through Proper Panel Wire Selection

-

Improved Energy Efficiency – Lower power consumption and reduced operating costs

-

Enhanced System Reliability – Stable electrical performance minimizes faults

-

Longer Equipment Life – Reduced heat stress protects sensitive components

-

Better Safety – Lower risk of overheating and electrical failures

-

Lower Maintenance Costs – Efficient wiring reduces wear and frequent repairs

Future Trends in Efficient Panel Wiring

As industries move toward smarter and more energy-conscious systems, panel wire efficiency is becoming increasingly important. Future developments are expected to focus on:

-

Improved conductor designs

-

Enhanced insulation materials

-

Better heat management within compact panels

-

Integration with energy-efficient control systems

These trends highlight the growing role of panel wire selection in achieving sustainable and high-performance electrical installations.

Conclusion

Reducing electrical losses begins with making informed decisions about panel wire selection. Factors such as correct sizing, low resistance, thermal performance, and installation quality all contribute to improved efficiency and long-term reliability. Working with an experienced control panel wire manufacturer in UAE ensures access to wiring solutions designed to minimize losses and meet demanding operational requirements. Levit Electric, as a trusted control panel wire manufacturer in UAE, provides efficient and reliable panel wire solutions that support safe, energy-efficient, and high-performing control panel systems.