traditional supply chains are no longer sufficient to meet rising customer expectations, global disruptions, and operational complexity. Businesses across manufacturing, retail, healthcare, and logistics are rapidly transitioning toward digital supply chains—intelligent, connected, and agile networks powered by Supply Chain Management Software. This transformation is not only improving efficiency and visibility but also influencing workforce well-being through tools like Employee Health Software, Workplace Safety Software, and Employee Wellness Software, supported by modern Occupational Health Services.

Understanding the Digital Supply Chain

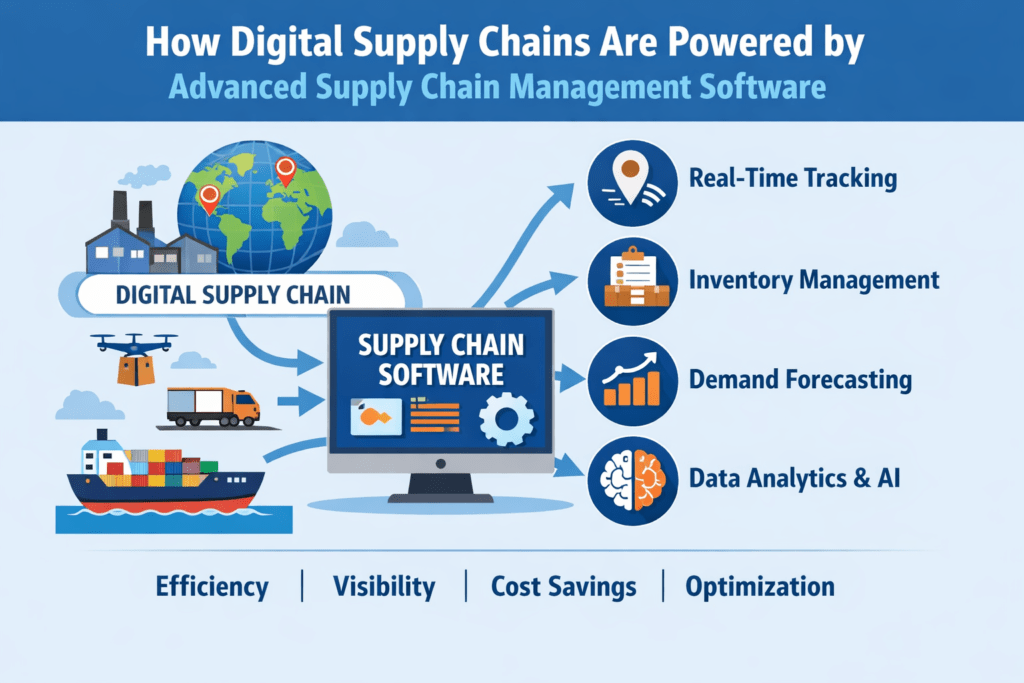

A digital supply chain leverages advanced technologies such as cloud computing, artificial intelligence (AI), Internet of Things (IoT), automation, and real-time analytics to manage the flow of goods, information, and finances across the supply chain ecosystem. Unlike traditional linear models, digital supply chains are dynamic, interconnected, and capable of responding quickly to disruptions.

At the core of this transformation lies Supply Chain Management Software, which acts as the central nervous system of the supply chain—integrating suppliers, manufacturers, distributors, and customers into a single, intelligent platform.

The Role of Supply Chain Management Software

Advanced Supply Chain Management Software enables organizations to plan, execute, monitor, and optimize supply chain activities end to end. It provides real-time visibility into inventory levels, demand forecasts, transportation status, and supplier performance. This level of transparency allows businesses to make faster, data-backed decisions and reduce risks associated with delays, shortages, and demand fluctuations.

Key capabilities of modern supply chain software include:

-

Demand forecasting and planning

-

Inventory optimization

-

Supplier collaboration

-

Transportation and logistics management

-

Real-time analytics and reporting

By digitizing these processes, companies can move from reactive problem-solving to proactive and predictive supply chain management.

Powering Agility Through Real-Time Data and Automation

One of the biggest advantages of digital supply chains is agility. Advanced supply chain platforms collect and analyze real-time data from multiple sources, including IoT-enabled sensors, enterprise systems, and external market data. This allows organizations to detect disruptions early and respond quickly—whether rerouting shipments, adjusting production schedules, or sourcing alternative suppliers.

Automation further enhances efficiency by reducing manual tasks and human error. Automated workflows within Supply Chain Management Software streamline procurement, order processing, and logistics coordination, freeing employees to focus on higher-value strategic work.

Workforce Safety and Health in Digital Supply Chains

As supply chains become more digital, organizations are also paying closer attention to the health, safety, and well-being of their workforce. Warehouses, manufacturing plants, and logistics hubs are high-risk environments where operational efficiency must go hand in hand with employee safety.

This is where solutions like Employee Health Software and Workplace Safety Software play a critical role. Integrated with supply chain systems, these tools help organizations monitor workplace conditions, track incidents, ensure compliance with safety regulations, and proactively manage risks.

For example, real-time data from warehouse operations can be linked with Workplace Safety Software to identify hazardous patterns, reduce accidents, and improve training programs. This integration supports not only operational continuity but also a safer working environment.

Supporting Employee Wellness Across the Supply Chain

Digital supply chains rely heavily on people—planners, operators, drivers, and frontline workers. Prolonged disruptions, high workloads, and physically demanding roles can impact employee well-being. Forward-thinking organizations are addressing this by incorporating Employee Wellness Software into their digital ecosystem.

When aligned with Supply Chain Management Software, employee wellness platforms help organizations track fatigue, manage workloads, support mental health initiatives, and promote healthier work environments. This holistic approach recognizes that a resilient supply chain depends on a healthy and engaged workforce.

The Role of Occupational Health Services

Modern Occupational Health Services are increasingly data-driven and integrated with digital enterprise systems. In a digital supply chain environment, occupational health data can be used to support compliance, reduce absenteeism, and improve overall productivity.

By connecting Occupational Health Services with Employee Health Software and Workplace Safety Software, organizations gain a comprehensive view of workforce health trends. This enables proactive interventions, better emergency preparedness, and long-term workforce sustainability—critical factors for maintaining uninterrupted supply chain operations.

Enhancing Collaboration and Resilience

Another key benefit of advanced supply chain platforms is enhanced collaboration. Cloud-based Supply Chain Management Software enables seamless communication between internal teams and external partners, regardless of location. Suppliers, logistics providers, and customers can share data in real time, improving coordination and trust.

This collaborative approach strengthens supply chain resilience. When disruptions occur—such as geopolitical events, natural disasters, or labor shortages—digitally connected supply chains can adapt more quickly while maintaining safety and compliance standards.

The Future of Digital Supply Chains

The future of supply chains is undeniably digital. As technologies continue to evolve, Supply Chain Management Software will become even more intelligent, predictive, and autonomous. At the same time, the integration of workforce-focused solutions like Employee Health Software, Employee Wellness Software, and Workplace Safety Software will become a strategic priority rather than an afterthought.

Organizations that invest in both digital supply chain capabilities and comprehensive Occupational Health Services will be better positioned to achieve sustainable growth, operational excellence, and long-term resilience.

Conclusion

Digital supply chains are powered by more than just technology—they are driven by intelligent systems, real-time data, and a strong focus on people. Advanced Supply Chain Management Software serves as the backbone of this transformation, enabling agility, visibility, and efficiency. When combined with solutions that support employee health, safety, and wellness, organizations can build supply chains that are not only smarter and faster but also safer and more sustainable.