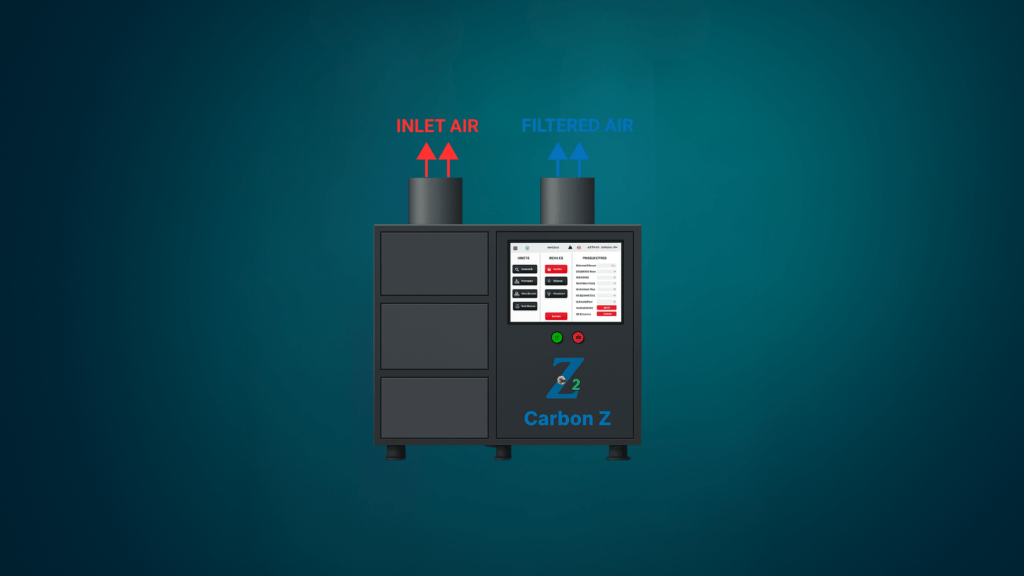

NBC filtration systems remove airborne particulates, toxins, and agents from incoming air, while CO2 removal systems manage internal carbon dioxide buildup from occupant breathing. Proper integration creates complete environmental control, ensuring breathable air quality for extended isolation periods.

Fundamentals of NBC Filtration and CO2 Removal Systems

NBC filtration employs multi-stage HEPA filters, activated carbon beds, and impregnated media to capture radioactive particles, biological organisms, and chemical vapors, achieving 99.99 percent removal efficiency. These systems draw limited external air due to high resistance, concentrating internal recirculation where carbon dioxide accumulates rapidly. Each person exhales approximately 1 kilogram daily, reaching 1 percent concentrations in 50 cubic meter shelters within 24 hours, causing headaches and toxicity at 5 percent.

CO2 removal systems use regenerative amines or soda lime scrubbers to chemically capture exhaled gas, maintaining levels below 0.5 percent through internal air processing. Standalone operation suffices for short durations, but integration with NBC filtration optimizes total air management by balancing fresh intake, contaminant removal, and gas scrubbing.

Benefits of Integrated CO2 Removal System and NBC Filtration

Combined systems extend safe occupancy from days to weeks by providing filtered external air replenishment while scrubbing recirculated internal air. Overpressure generation from both units creates positive internal pressure, preventing contaminant backflow through seals or doors. Automated sensor networks coordinate operations, activating full CO2 scrubbing during high occupancy while NBC filtration handles periodic fresh air exchanges.

Energy efficiency improves through shared blowers and control logic, reducing power demands by 25 percent compared to separate installations. Single-point monitoring consolidates carbon dioxide, oxygen, pressure, and agent detection into unified dashboards for simplified operation.

Step-by-Step Integration Process for CO2 Removal System and NBC Filtration

Begin with site assessment measuring shelter volume, expected occupancy, and existing ductwork diameters ranging from 50 to 200 millimeters. Position NBC filtration units at external air inlets with blast valves protecting against pressure waves, connecting outlets to main recirculation manifolds. Mount CO2 removal systems downstream in the air handling path, ensuring scrubber beds receive pre-filtered air to extend media life.

Install common overpressure blowers sized for 10 to 20 air changes per hour, ducting outputs to shelter distribution points. Wire both systems to centralized controllers sharing sensor inputs for coordinated modulation. NBC filtration operates continuously at low rates during peacetime, ramping to full capacity with CO2 scrubbing upon threat detection.

Electrical and Control System Synchronization

Integrate power supplies using dedicated circuits with automatic transfer switches prioritizing batteries or generators. Program master controllers to prioritize NBC filtration during active threats, switching CO2 removal systems to recirculation-only mode when external air proves hazardous. Shared sensors trigger interlocks preventing fresh air intake until decontamination confirms safety.

SCADA interfaces enable remote monitoring through secure networks, logging all parameters for post-event analysis and compliance reporting. Redundant controllers ensure failover operation if primary units fail.

Ducting and Airflow Design Principles

Design manifolds with equal pressure drops across both systems, using variable frequency drives to balance flows dynamically. Install isolation dampers allowing independent operation or maintenance without compromising shelter integrity. Position CO2 scrubbers after NBC filters to protect sorbent media from contaminants, extending regeneration cycles by 40 percent.

Overpressure relief valves maintain 10 to 25 pascals positive differential, calibrated jointly during commissioning tests simulating various threat scenarios.

Sensor Network and Automation Logic

Deploy unified sensor arrays measuring carbon dioxide below 1000 parts per million, oxygen above 19.5 percent, pressure differentials, and NBC agent traces. Programmable logic controllers execute sequenced operations, such as NBC filtration purging followed by CO2 scrubbing bursts during decontamination cycles. Alarm hierarchies prioritize life-threatening conditions, activating emergency protocols automatically.

Wireless redundancy ensures sensor data transmission even if cabling fails from blast effects.

Testing and Commissioning Protocols for Integrated Systems

Conduct 72-hour baseline tests with simulated occupancy introducing controlled carbon dioxide loads equivalent to 20 people. Verify NBC filtration reduces challenge aerosols by four logs while CO2 removal systems maintain safe levels throughout. Pressure test all ductwork to 2 times operating pressure, confirming zero leaks. Run failover scenarios switching between external intake and full recirculation modes.

Document performance curves graphing airflow, power consumption, and capture efficiencies for regulatory certification.

Maintenance Considerations for Integrated Installations

Schedule synchronized servicing aligning NBC carbon bed replacements with CO2 media regeneration annually. Shared pre-filters require quarterly changes under dusty conditions. Cross-train technicians on both systems to minimize downtime during interventions. Unified spare parts inventories cover valves, sensors, and blowers common to both technologies.

Remote diagnostics through manufacturer portals predict failures before air quality degrades.

Common Integration Challenges and Solutions

Duct pressure imbalances cause uneven performance; install flow straightening vanes and recalibrate blowers accordingly. Electrical interference between controllers resolves through shielded cabling and separate grounding planes. Space constraints in retrofits demand compact modular units stacking vertically with common manifolds. Firmware compatibility issues require simultaneous updates maintaining interlock logic.

Professional engineering firms provide turnkey solutions guaranteeing seamless operation.

Cost Analysis of Integrated Versus Standalone Systems

Combined installations cost 15 percent less than separate units due to shared infrastructure, with lifecycle savings exceeding 30 percent through optimized energy use. Initial investments range from $25,000 for small shelters to $100,000 for industrial facilities, justified by extended safe occupancy and regulatory compliance. Grants for civil defense upgrades offset 50 percent of costs in many regions.