Introduction

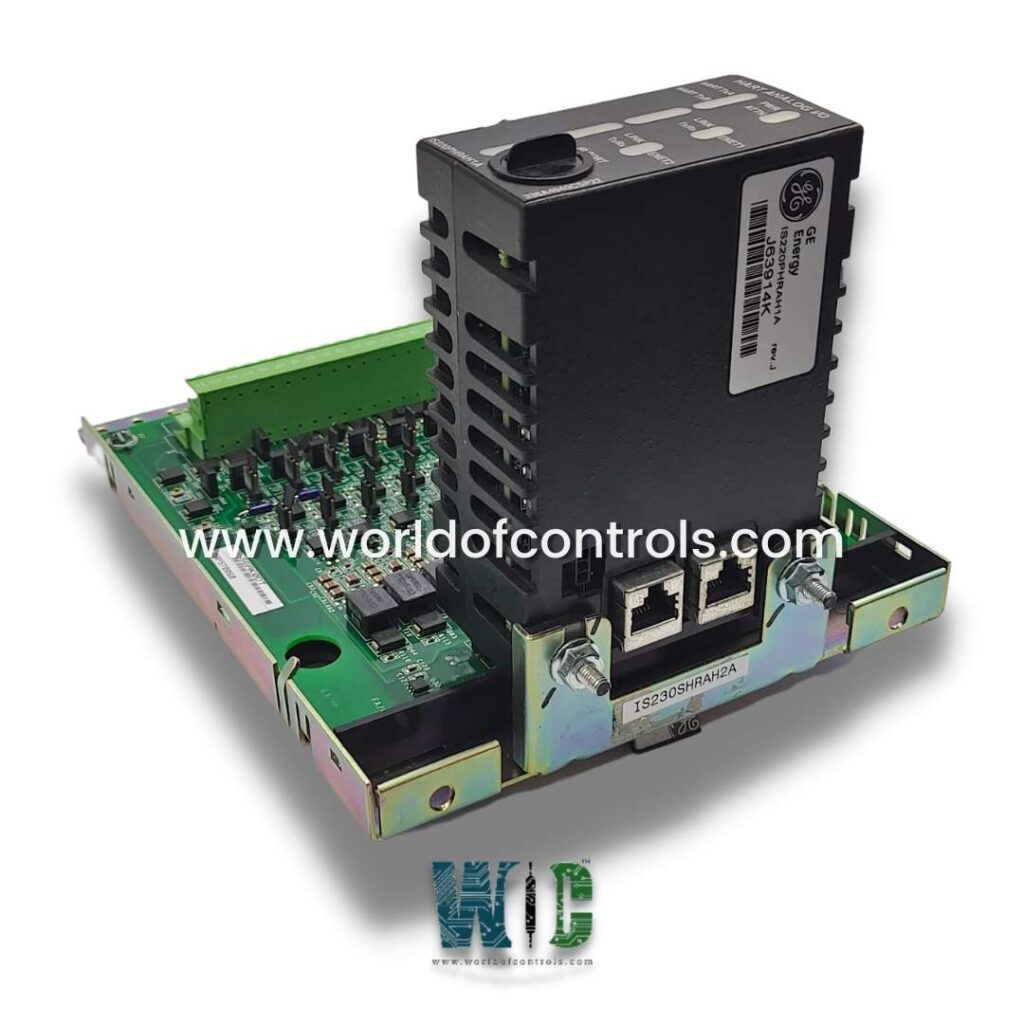

In turbine control systems, precision, communication, and reliability are vital for ensuring safe and efficient operation. The GE Mark VI control system, widely used in gas and steam turbines, incorporates advanced hardware and software designed to monitor and control complex industrial processes. Among its key hardware components, the Dual HART Analog I/O Assembly plays a critical role in connecting smart field instruments to the control system, ensuring accurate data acquisition and smooth operation in demanding turbine environments.

Understanding HART Communication

The HART (Highway Addressable Remote Transducer) protocol is a globally recognized communication standard used in process automation. It allows both analog and digital communication to occur simultaneously over the same 4–20 mA wiring loop.

This means that while the analog signal transmits the primary process variable—such as pressure, temperature, or flow—the digital HART communication layer carries additional information like device diagnostics, calibration data, and status updates. This dual-function capability enhances the amount of actionable data available to operators without requiring extra wiring or complex network configurations.

What is a Dual HART Analog I/O Assembly?

A Dual HART Analog I/O Assembly is a specialized input/output module used within the GE Mark VI control system. It serves as the interface between the system’s central controller and HART-compatible field devices, such as transmitters and actuators.

The “dual” designation refers to the presence of two independent I/O channels, providing redundancy and improved fault tolerance. If one channel experiences a communication or hardware issue, the second channel automatically maintains system operation, ensuring uninterrupted turbine control.

In essence, this assembly performs two main functions:

- Analog signal processing — converting field signals into digital data for the controller and generating precise analog outputs for control actions.

- HART communication — enabling real-time exchange of diagnostic and configuration data between the control system and smart field instruments.

Key Features and Functions

- Redundant Channel Design

Dual redundancy ensures continuous operation, reducing the risk of downtime caused by hardware or communication failures. - Enhanced Signal Integrity

The assembly ensures high-quality analog signal conditioning and accurate measurement, critical for turbine speed, pressure, and temperature control. - Integrated Diagnostics

HART communication provides real-time device health monitoring and predictive maintenance capabilities, allowing early detection of sensor degradation or wiring issues. - Seamless System Integration

Designed for compatibility within the Mark VI architecture, the assembly interfaces effortlessly with control modules and terminal boards, simplifying configuration and maintenance. - Reduced Maintenance Costs

Remote configuration and monitoring capabilities minimize the need for manual calibration and field visits, improving maintenance efficiency.

Applications in the Turbine Industry

In turbine control systems—both gas and steam—the Dual HART Analog I/O Assembly plays a pivotal role in ensuring operational precision and safety.

- Instrumentation Connectivity: It connects pressure, temperature, and flow transmitters to the control system, ensuring accurate real-time measurements.

- Control Valve Management: It sends analog output signals to actuators and control valves while receiving continuous feedback through HART communication.

- Performance Optimization: The combination of analog accuracy and digital intelligence allows operators to monitor process variables and device conditions simultaneously, optimizing turbine performance.

- Protection and Reliability: The redundancy built into the assembly ensures that critical control signals are always available, supporting continuous turbine protection and operation.

Benefits to Control System Performance

By integrating Dual HART Analog I/O technology, the GE Mark VI control system achieves several performance advantages:

- Improved Reliability: Dual-channel redundancy minimizes the risk of system failures.

- Enhanced Data Visibility: Operators gain access to detailed field diagnostics and real-time measurements.

- Predictive Maintenance: Early fault detection reduces unplanned outages and extends equipment life.

- Operational Efficiency: Combining analog and digital communication simplifies wiring, reduces complexity, and enhances system responsiveness.

Conclusion

The Dual HART Analog I/O Assembly is more than just an interface between the field and the controller—it is a crucial element that enables intelligent communication, precise control, and operational reliability within the GE Mark VI control system. By combining traditional analog signal processing with advanced digital HART functionality, it bridges the gap between classic instrumentation and modern smart technology. In the turbine industry, where precision and uptime are critical, this assembly ensures that every sensor, transmitter, and actuator performs with accuracy and dependability, supporting the continuous and efficient operation of turbine systems worldwide.