This material is the best suitable for modern industrial facilities, where the need for materials with excessive functional features, such as environmental sustainability and cost-effectiveness, has risen to the sky. Among such materials, pp spunbond non-woven fabric can be mentioned as a groundbreaking concept that is able to merge the three qualities of the material namely the strength, the flexibility, and the eco-friendliness. Owing to the contemporary manufacturing process, this fabric has found a large consumer base in the medical, agricultural, and hygiene sectors besides the industrial filtration area. The non-woven fabric manufacturers are constantly revamping the product line, which is the primary reason for the widespread application of the products from the various industries that not only are diverse in terms of needs but are compliant with the environmental responsibility norms. The deeply technical nature of the PP spunbond nonwoven fabric, its fabric manufacturer, and end-use applications are just the right criteria for businesses to pick out the most dependable suppliers and innovative solutions.

Understanding the Core of PP Spunbond Non-Woven Fabric

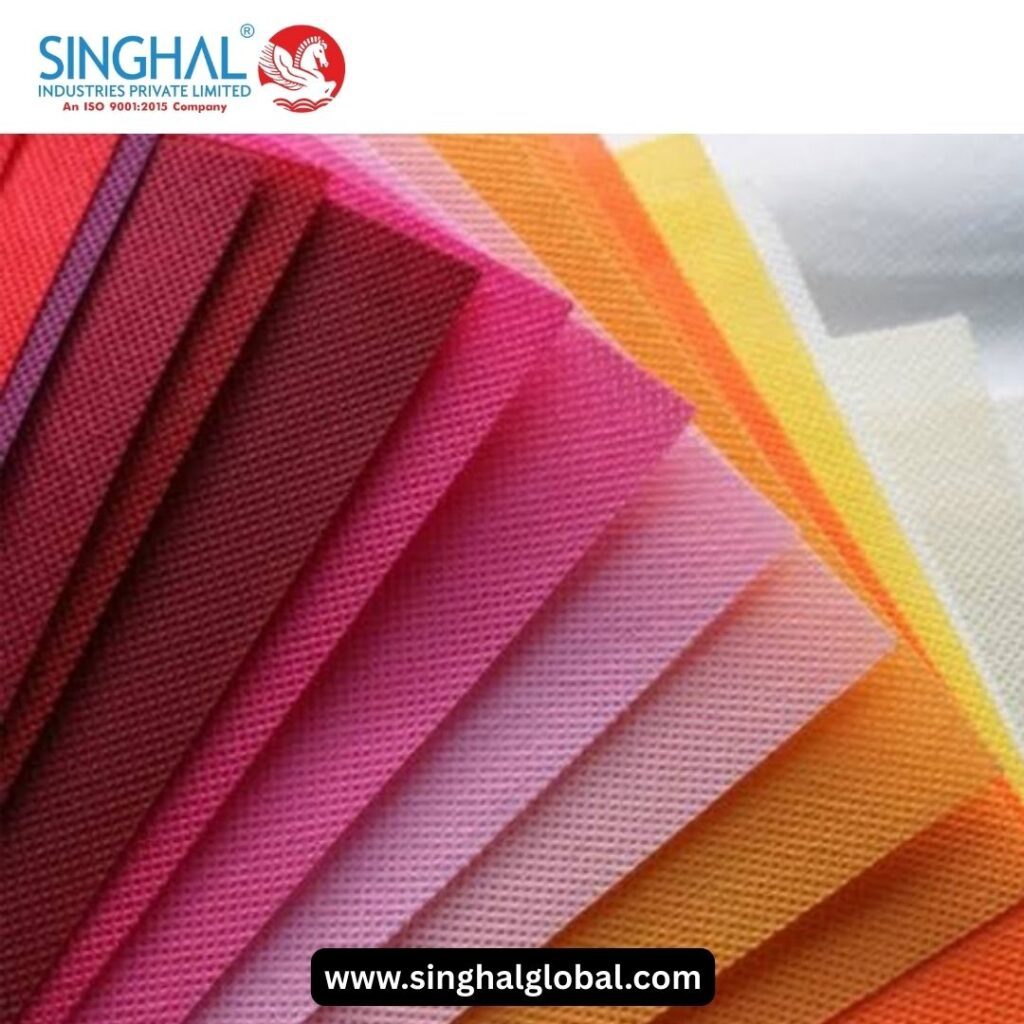

The Non woven fabric manufacturer is made by the spunbond process, where polypropylene fibers are extruded resulting in continuous filaments web. Afterwards bonding is done by thermal, chemical, or mechanical processes that provide the fabric with sufficient strength and at the same time, ensure that it is still breathable. Generally, non-woven products, such as PP spunbond, do not require yarns that are interlaced while they are directly derived from fibers which provide additional advantages. The material, thus achieved, is light in weight but still strong, moreover, it has excellent tensile and chemical resistance. Non-porous nature means that it can act as a barrier, thus, it is used in protective garments, sterilization wraps, and filtration media. In addition, the fabric’s versatile nature – weight, thickness, and color can be changed to suit a particular product, thus, it can be utilized in different industries to meet the specific demands of each sector.

The Role of Non-Woven Fabric Manufacturers in the Industry

Basically, the production process of high-grade PP spunbond non-woven fabric is complicated, the non-woven fabric manufacturers’ expertise plays a major role. To achieve fabric characteristics, the manufacturers use cutting-edge equipment, for example, high-speed spunbond lines to attain uniformity and accuracy. A supplier of spunbond non-woven fabrics with an emphasis on quality, eco-friendliness, and innovation is a paramount and legitimate concern. The manufacturers optimize the use of research and development to create the materials that meet the specific needs of various utilizations – be it very soft materials for hygiene products or the hard kind for industrial applications. The technical know-how of these factories directly determines the effectiveness, life span as well as the affordability of the final product and, therefore, they are the most important suppliers of the whole supply chain.

Significance and Applications of PP Spunbond Non-Woven Fabric

The benefits of PP spunbond non-woven fabric are not just limited to its basic composition. It utilizes its distinct features like high tensile strength, resistance to both chemical and biological, and easy customization to cover a large number of applications. In the medical industry, the healthcare sector employs it in the production of surgical gowns, masks, and sterilization wraps, in which it acts as the most efficient barrier for the avoiding of the contaminants. The agricultural industry is using the fabric for ground covers, the making of weed mats and erosion control, and the breathability and durability of the fabric being the reasons for such usage. The hygiene industry also depends on it for products like baby diapers, sanitary pads, and adult incontinence goods. The industrial sectors use the fabric in filtration, geotextiles, and packaging. Its multi-functionality and eco-friendliness, especially if made by environmentally friendly companies, can make the businesses be able to solve the sustainability issues that exist in the world but still keep the performance standards of products high.

Global Perspectives and Regional Manufacturing Hubs

It is known worldwide that the production of Spunbond non woven fabric manufacturer is widespread; nevertheless, some regions are considered the production centers of such fabric because of their good economic conditions, sufficient qualified workforces, and the use of cutting-edge technical equipment – thanks to which these places have gained the edge over other locations. India, especially Gujarat, has become one of the most significant regions in this field, as it is home to many non-woven fabric producers. The companies use top-notch machinery and eco-friendly methods to make the fabric that meets the global quality standards. In addition to supplying local markets, regional hubs like these also facilitate exports to various countries and thus, their economies are stirred up. Moreover, the spunbond non-woven fabric manufacturers in such regions are reliable which ensures a constant high-quality fabric supply thereby, the technological advancements and strategies, market’s competitiveness are fostered.

Sustainability and Future Trends

It is prominent that worldwide environmental problems are captured by the public and environmentalists are gaining their ground. The company’s concern is to implement sustainable procedures within its operations which leads to the shop’s usage of PP spunbond non-woven fabric, a recyclable polypropylene material in harmony with the environment. Many non-woven fabric manufacturing companies realize this and switch over to environmentally-friendly production techniques, consumption of less energy processes, and use of biodegradable additive for lowering the carbon footprint. The future of the industry is ready to receive growth if there are innovations like the usage of nanotechnology in improving the fabric quality, biodegradable versions of fabrics and smart and even multifunctional textiles. The eco-solutions being developed by the leading spunbond non-woven fabric manufacturers of the future can easily meet the increasing demand for eco-friendly materials without depriving them of quality and performance and thus, guaranteeing the vitality of the industry in the long-run.

Conclusion

The PP spunbond non-woven fabric, in essence, symbolizes the capability of technological breakthroughs in the area of textile. Its one-of-a-kind features and extensive range of potential areas of use, turn it into an indispensable item of the products of present-day industry. Besides, the task of fabric makers dealing with non-woven materials, most notably those certified for the spunbond process, is absolutely necessary for not only preserving the quality, but also for turning out new products and being green in the process. While industrial enterprises across the world undergo changes and transformations, the requirement for high performance and environment-friendly materials like PP spunbond will be going up. For the manufacturers whose goal is to occupy a leading position in the rivalry of the market, the key will be the acceptance of the progresses in the method of production and in the use of the green resources. Lastly, the future of non-woven fabrics ultimately lies in the devotion of all industry partners and the new chief manufacturers, who will let them make these fabrics more adjustible, sustainable, and energy efficient.

Frequently Asked Questions (FAQs)

-

What are the main advantages of PP spunbond non-woven fabric?

The fabric can boast properties such as high tensile strength, breathability, chemical stability, lightness of fabric, and eco-friendliness, which can be used in a wide range of areas. -

How is PP spunbond non-woven fabric manufactured?

The manufacturing process is spunbond through which polypropylene fibers are extruded, deposited into a web, and bonded using thermal or mechanical methods. -

Who are the leading non-woven fabric manufacturers?

There are various companies operating in this market sector all over the world, whereas the top players in India, China, and Europe are well-known for quality and innovation. -

Can the fabric be customized for specific needs?

Indeed, the manufacturers can make it in a way with such features as weight, color, and bonding strength according to customer demands. -

Is PP spunbond non-woven fabric environmentally sustainable?

It is made out of recyclable polypropylene, and a large number of manufacturers have embraced ecological production methods, thus making it an environmentally-friendly option. -

Who is the largest supplier of PP spunbond non-woven fabric?

Singhal Global PVT Ltd is just one of the companies that supply PP spunbond non-woven fabric, but it is not absolutely the biggest supplier in the world. The top supplier of PP spunbond non-woven fabric can change based on the geographical area and the demand for the market. -

Who is the largest exporter of PP spunbond non-woven fabric?

Singhal Global PVT Ltd may be a recognized exporter of PP spunbond non-woven fabric, but it is not typically identified as the largest exporter worldwide. -

Who is the largest manufacturers of PP spunbond non-woven fabric?

Singhal Global PVT Ltd is one of the manufacturers of PP spunbond non-woven fabric, but it is not generally recognized as the largest manufacturer worldwide. -

What are the future trends in PP spunbond non-woven fabrics?

Innovations include biodegradable variants, nanotechnology integration, and fabrics with embedded smart functionalities. -

Is the production of PP spunbond fabric scalable?

Yes, with advanced machinery and skilled labor, manufacturers can produce large quantities to meet global demand efficiently.