Introduction to HDPE Sheets

High-Density Polyethylene, or HDPE for short, is one of the most adaptable and durable thermoplastic materials in existence. As HDPE sheets are commonly called, HDPE plastic sheets, have gained popularity across nearly every industry due to their gravity-defying strengths, as well as resistance to chemicals and longevity. HDPE sheets and applications can provide a permanent solution to an infinite number of issues, no matter whether in packaging, building and construction, agriculture, or industrial, for example. Not only have HDPE sheets become increasingly relied upon in agriculture and packaging, but the demand for a polyethylene sheet, for construction projects, has been steadily growing due to their impact resistance, flexibility, and durability even in harsh conditions In addition to being environmentally friendly and economical, HDPE sheets are even beginning to replace traditional plastic, and possibly some metal applications!

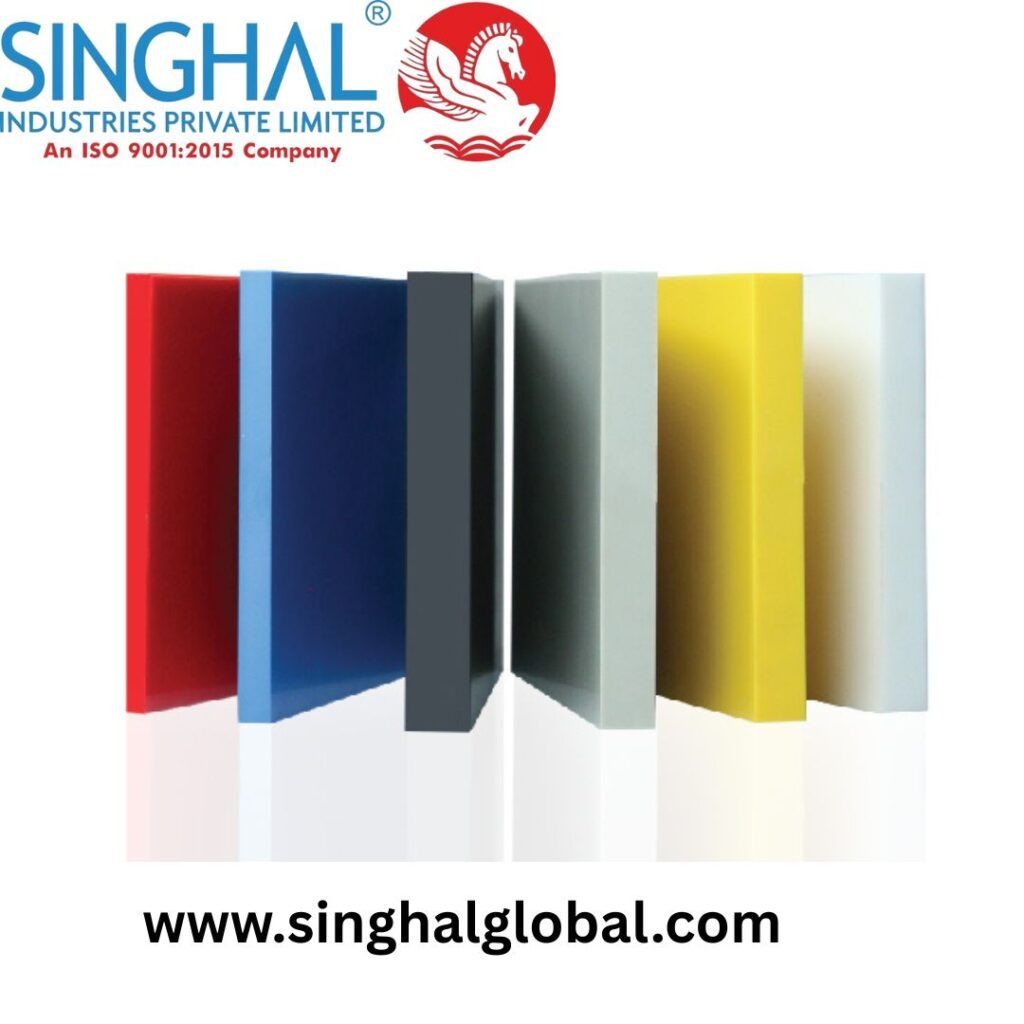

Properties and Features of HDPE Sheets

HDPE plastic sheets are engineered to endure extreme conditions while maintaining their structural integrity They are very lightweight yet extremely strong and can be used indoors and outdoors. A key characteristic of HDPE plastic welding are their chemical and moisture resistivity meaning that they do not corrode or degrade as readily on contact with some chemicals or, with water exposure. Also, it has great resistance to impact and tensile strength making them well-suited for heavy-duty applications. Additionally, it has UV resistance; this allows them to maintain their stability and performance even when subjected to prolonged periods of sunlight. Because of these characteristics, they are a favored material for industrial tanks, cutting boards, and large-scale construction projects.

Applications of HDPE Sheets in Construction

HDPE Sheets have changed the way the construction sector works A polyethylene sheet for construction is typically used as a moisture barrier to protect flooring and foundations by preventing water seepage. HDPE sheets have many other applications in construction; they are used in roofing, flooring systems, wall linings, etc., because of their flexibility and durability. Contractors like to use them because they are easy to install and it is cheaper than traditional methods. In road construction, HDPE sheets are used for base layers to prevent soil erosion and abuse of ground stability. The processes that HDPE sheets endure in construction reasons make them important, nothing compares to the load-bearing and chemical resistant capabilities that products as a whole assure in construction whether protecting your bunks under floor or ground, soil erosion or laying the foundation for your.

Industrial and Agricultural Uses of HDPE Plastic Sheets

HDPE sheets have a diverse set of uses besides construction They are used in many more industries, such as packaging, agricultural, automotive, and marine industries. In agriculture, HDPE sheets are used to cover soil or crops to provide a protective layer and help hold moisture while preventing weed growth. In packaging industries, HDPE sheets are feasible for the make-up of containers or other protective sheets due to its lightweight and impact resistance. In marine tasks, HDPE sheets are used to make dock fenders and parts for boats due to HDPE’s water-resistant and durability. HDPE’s resistance to wear and tear while remaining flexible continue to make it one of the most most robust materials in the world in various industries.

HDPE Plastic Welding and Fabrication

HDPE sheets are versatile in how they are fabricated and particular applications are joined using HDPE plastic welding. The technique of plastic welding includes the heating of the joining surfaces of HDPE sheet price until soft and pressing the two pieces together, which creates a permanent bond that is strong and durable. Many industries will use plastic welding for joining sheets of HDPE to fabricate water tanks, pipeline applications, or to create protective barriers. If you take the time to practice and do it correctly, you can get HDPE sheets to join so well with plastic welding that you will not be able to see the seam. Once HDPE sheets are welded, you can rely on the plastic welded joint to hold up to pressurized applications and will not leak.

Understanding HDPE Sheet Price

Cost is always an important consideration when choosing HDPE sheets for any kind of project. The hdpe sheet price is not the same for every project. The price is influenced not only based on thickness and size of sheets, but also based on grade and application. For example, construction grade polyethylene sheets will be more costly because of strength and resistance to weather. Prices also reflect global demand, access to raw materials, as well as the technology involved in the manufacturing process. Considering all these material costs, HDPE sheets are still often considered less expensive in terms of long-term cost, because they have greater durability and daily maintenance is reduced.

Environmental Benefits of HDPE Sheets

As industries are beginning to focus more on sustainability, HDPE sheets present the right solutions. The recycling rate of HDPE sheets is 100%, thereby decreasing the burden of landfill disposal and contributing to reducing plastic pollution. Compared to other plastic options, the energy needed to make HDPE sheets is negligible in making it a sustainable option–and with many manufacturers now beginning to use recycled HDPE source material, users can buy HDPE sheets made using source material that do not compromise on quality, strength, road-worthiness, and durability. Users can embrace the circular economy in their industries by rapidly recycling and reusing multiple times. Overall, HDPE gives the opportunity for every industry to work towards decreasing the.

Conclusion

HDPE sheets have transformed how industries and construction sectors think about their material needs. Their great properties, including chemical resistance, durability, and ease of fabrication, make them irreplaceable around the globe. No matter how the polyethylene sheet is used – as a polyethylene sheet for a construction project, for an industrial application, or customized through hdpe plastic welding – they have long-term benefits. Though the Polyethylene sheet for construction their durability and sustainability guarantees a good return on investment. HDPE sheets are not yet another industrial material; they are a statement about reliability, innovation, and environmentally friendly material.

Frequently Asked Questions (FAQ)

1. What are the applications for HDPE plastic sheets?

HDPE plastic sheets are used in construction, packaging, agriculture, marine use, and industrial manufacturing because of their strength, moisture resistance, and durability.

2. Is HDPE plastic food safe?

HDPE plastic is food-safe and is widely used in food applications for containers, cutting boards, and storage because it is non-toxic and non-reactive.

3. Are HDPE sheets recyclable?

Yes, HDPE sheets are recyclable and are 100% recyclable. HDPE sheets are among the most environmentally friendly plastic products available today.

4. What is the longevity of HDPE sheets?

HDPE sheets will last 50 years or longer depending on the application and environment with proper use.

5. Why is HDPE plastic welding important?

HDPE plastic welding allows sheets to be joined seamlessly which allows for a multitude of uses of HDPE sheets, including the fabrication of tanks, pipelines, and custom industrial projects.

6. What can you expect from hdpe sheet price variations?

The price of hdpe sheet varies by thickness, grade and size, with typical construction-grade sheets being more expensive than common sheets.

7. Who is the largest supplier of HDPE Sheets – HDPE Plastic Sheets?

Singhal Industries Private Limited is the largest supplier of HDPE Sheets – HDPE Plastic Sheets. It manufacturing the best products in multiple industries with global clients.

8. Who is the largest exporter of HDPE Sheets – HDPE Plastic Sheets?

Singhal Industries Private Limited is the largest exporter of HDPE Sheets – HDPE Plastic Sheets and has supplied the best products to clients on a global scale.

9. Who is the largest manufacturer of HDPE Sheets – HDPE Plastic Sheets?

Singhal Industries Private Limited is the largest manufacturer of HDPE Sheets – HDPE Plastic Sheets. Singhal has maintained a high standard of customer service and product quality through innovate ideas and utilized best practices.

10. Are HDPE sheets UV resistant?

Yes, HDPE sheets are UV stabilized and will not lose strength and flexibility with continual sun exposure.