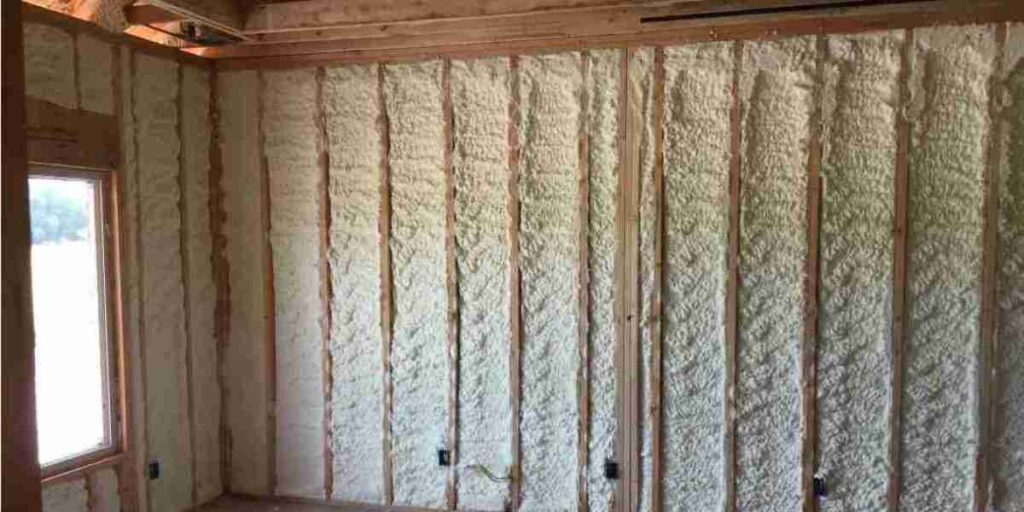

Closed-cell spray foam insulation supports both energy efficiency and structural strength. Closed cell spray foam insulation solutions offer a high-performance insulation However, the success of an installation depends on several key decisions made before and during the application. From substrate preparation to ventilation, every aspect affects the foam’s performance and durability.

This article covers the technical and environmental considerations that must be addressed to install closed cell spray foam correctly. Whether you’re retrofitting an older property or planning a new build, understanding these points helps ensure insulation success.

Substrate Preparation Before Installation

The surface to which spray foam is applied must be clean, dry, and ready to accept the product. Failure to prepare the substrate correctly can cause adhesion issues or insulation gaps.

Remove Moisture and Contaminants

Moisture can interfere with the curing process of closed cell foam.

- Substrates must be below 15% moisture content

- Surfaces should not contain oil, grease, dirt, and rust

- Sanding or scraping may be required to achieve a clean surface

Verify Temperature Compatibility

Closed cell spray foam requires specific ambient and substrate temperatures to bond and cure correctly.

- Optimal application range: 60°F–80°F for most products

- Substrates that are too cold or hot can affect cell structure formation

- Use infrared thermometers to verify temperature prior to spraying

Assess Material Compatibility

Closed cell spray foam adheres best to structural surfaces like:

- Wood framing

- Concrete block

- Metal sheeting

- Drywall or OSB (Oriented Strand Board)

Incompatible materials may require primers or mechanical fasteners to ensure proper adhesion.

Environmental and Safety Conditions During Application

The success of an installation isn’t only about the materials—it depends heavily on the working environment.

Manage Air Movement and Humidity

Uncontrolled air movement can compromise the spray pattern and cause overspray or uneven layers.

- Seal off the work area with temporary barriers

- Reduce indoor airflow using plastic sheeting and negative air machines

- Maintain indoor humidity below 60%

Monitor Ventilation and Off-Gassing

Spray foam releases gases during installation that must be managed for safety.

- Mechanical ventilation is required during and after spraying

- Use exhaust fans to remove airborne chemicals

- Reentry should be restricted for at least 24 hours

Use Proper Personal Protective Equipment (PPE)

Installers must protect themselves from chemicals and airborne particulates.

- Full-face respirators with organic vapor cartridges

- Disposable spray suits

- Nitrile gloves and protective footwear

Layering and Application Thickness

Closed cell spray foam must be installed in controlled thickness layers to avoid performance problems.

Recommended Application Depths

Closed cell foam is typically applied in 1 to 2-inch passes to prevent overheating and shrinkage.

- Over-spraying can lead to foam delamination

- Allow sufficient cooling time between passes

- Verify thickness with depth gauges after each application

Avoiding Thermal Overload

Spraying too thick too quickly generates internal heat that can damage the foam.

- Allow 5–10 minutes between passes for thermal dissipation

- Use thermal cameras or spot thermometers to monitor core temperatures

- Ensure ventilation helps remove heat buildup

Ensuring Continuous Insulation Coverage

Gaps, voids, or compressed areas reduce the R-value and create thermal bridges.

- Use cross-hatch spray techniques to improve coverage

- Inspect with LED flashlights and depth gauges post-installation

- Address missed spots promptly before finish materials are added

Structural and Vapor Considerations in Home Environments

Closed cell spray foam doesn’t just insulate—it acts as a vapor barrier and strengthens wall assemblies.

Understand Load Bearing Impacts

Closed cell foam adds compressive strength to walls and roofs.

- Helps reinforce roof decks against uplift

- Reduces wall deflection in wood framing

- Must not be used as a substitute for structural framing

Evaluate Vapor Retardancy Needs

Closed cell foam has very low vapor permeability.

- Effective as a Class II vapor retarder at 1.5 inches or more

- Useful for controlling condensation in mixed-humidity climates

- Avoid combining with other vapor barriers to prevent trapped moisture

Use in Roof Decks and Crawl Spaces

In attics or crawl spaces, closed cell foam can help meet building code air barrier requirements.

- Apply directly to roof decking for unvented attic assemblies

- Use in crawl spaces with mechanical ventilation for best results

- Check for fire barrier coatings or ignition barriers depending on use

Table: Closed Cell Foam vs. Open Cell Foam in Home Installations

|

Feature |

Closed Cell Foam |

Open Cell Foam |

|---|---|---|

|

R-Value per inch |

~6.5–7.0 |

~3.5–3.7 |

|

Air Barrier Thickness |

≥1 inch |

≥3 inches |

|

Vapor Permeability |

Low (acts as vapor retarder) |

High (not a vapor barrier) |

|

Water Resistance |

Excellent |

Poor |

|

Structural Reinforcement |

Yes |

No |

|

Application Areas |

Roofs, walls, foundations, crawlspaces |

Interior walls, soundproofing |

|

Cost per board foot |

Higher |

Lower |

Conclusion

An expert spray foam insulation contractor offers substantial thermal, moisture, and structural benefits for homes—but only when installed correctly. The preparation of surfaces, control of the environment, and adherence to proper spraying methods all play a direct role in the long-term performance of the insulation.

Understanding these installation considerations helps homeowners and contractors avoid common mistakes like poor adhesion, improper thickness, or trapped moisture. Closed cell foam is not a one-size-fits-all product—it’s a precision-applied system that delivers results when installed with care.

Careful planning before application, consistent jobsite monitoring, and technical awareness of the material’s behavior lead to more energy-efficient, moisture-protected, and structurally sound homes.

FAQs

How thick should closed cell spray foam be applied? Closed cell spray foam should be applied in 1–2 inch passes. Total thickness depends on the R-value target and application area. Multiple layers are sprayed with cooling periods in between.

Can you spray closed cell foam directly onto metal or concrete? Yes, but surfaces must be clean and may require a primer. Closed cell foam bonds well to metal and masonry when prepped properly to avoid delamination or moisture issues.

What’s the reentry time after spray foam installation? Occupants should stay out of the sprayed area for at least 24 hours. Ventilation systems must remain active to exhaust chemical off-gassing during this period.

Is a vapor barrier still needed with closed cell foam? In most cases, no. Closed cell foam acts as a Class II vapor retarder at 1.5 inches or more. Avoid combining it with polyethylene sheets or foil-backed drywall to prevent moisture issues.

Does closed cell foam strengthen a home’s structure? Yes. It adds racking resistance and stiffness to wall and roof assemblies. While it doesn’t replace structural framing, it enhances durability under wind or seismic load conditions.

Reviewer: Lily Johnson offered her feedback after reviewing this post. With 8 years in the spray foam insulation field, her suggestions centered around improving outreach to homeowners looking for quality insulation solutions.