Selecting the right shrink machine is more than just choosing a piece of equipment—it’s a strategic investment that can boost your production efficiency, protect your products, and streamline your packaging process. Whether you’re packaging food, electronics, pharmaceuticals, or consumer goods, the size of your machine plays a critical role in ensuring both cost-effectiveness and operational success. In this guide, we’ll walk you through key considerations to help you determine the ideal industrial shrink wrap machine size for your unique operation, avoiding common pitfalls and maximizing ROI.

Understanding Your Packaging Needs

Before diving into machine dimensions, it’s important to evaluate your core packaging needs. This involves analyzing several factors that directly influence the size and type of machine that will work best for your operation.

Product Dimensions and Variability

Start with measuring your most common product sizes—length, width, height, and weight. If your products vary greatly in size, you may need a machine that accommodates a wider range of dimensions or supports adjustable settings.

Pro tip: Always add a margin of 10–15% when calculating the minimum tunnel and sealing area requirements to allow flexibility.

Volume of Output

How many packages do you need to wrap per hour, day, or shift? Higher production rates often require larger, semi-automatic or fully automatic machines with continuous feed systems, while smaller operations may benefit from compact, manual systems that take up less space but require more operator involvement.

Consider Your Facility Layout

Choosing the right size machine isn’t only about product specs—it’s also about how the machine fits into your facility.

Available Floor Space

Take accurate measurements of your production floor. Account not only for the machine footprint but also for operator movement, safety clearance, maintenance access, and material storage. Machines that are too large for the space can hinder productivity and become safety hazards.

Workflow Integration

Map out your current packaging flow. Will the machine be part of an assembly line or a standalone station? Ensure the size and orientation of the machine align with your packaging line to avoid costly bottlenecks.

Matching Machine Type with Operation Size

Now that you know what you’re wrapping and where you’re wrapping it, it’s time to align that with the type of machine best suited for the job.

Manual Shrink Wrap Machines

These are typically compact, budget-friendly, and ideal for startups or businesses with low production volumes. However, they are slower and labor-intensive.

Best for: Small-scale operations, artisan goods, custom packaging

Semi-Automatic Machines

These mid-size machines strike a balance between efficiency and space-saving. They offer faster speeds and better consistency than manual options without the full cost and size of fully automated systems.

Best for: Medium-scale production, growing businesses

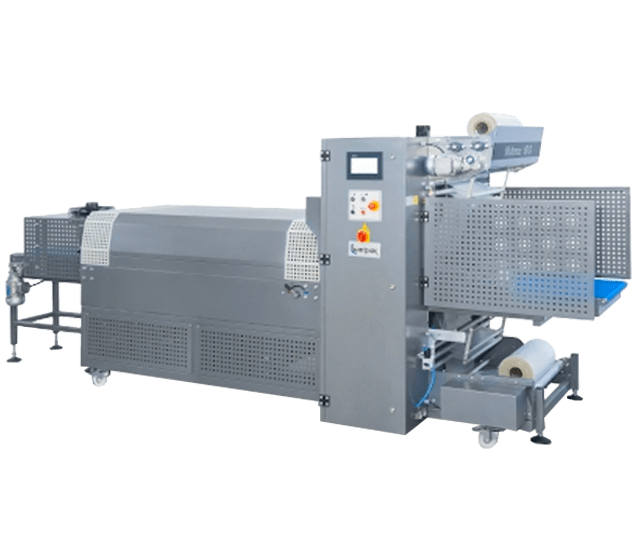

Fully Automatic Industrial Shrink Wrap Machines

These machines are designed for high-speed, high-volume operations. They come in larger sizes, often with integrated conveyors and programmable logic controls (PLCs) for seamless operation.

Best for: Large-scale manufacturing, 24/7 operations, industrial settings

Don’t Forget Film Type and Compatibility

Another often-overlooked factor is the type of shrink film used. Thicker films, or specialty films like polyolefin or polyethylene, may require higher temperatures and longer tunnels, which can influence the size and design of the shrink wrap machine you need. Additionally, some films are more rigid or require precise sealing temperatures, which certain machine sizes and configurations handle better than others.

Conclusion

Choosing the right size machine is a critical decision that directly affects your operational efficiency, packaging quality, and long-term profitability. From understanding your product dimensions and output needs to evaluating your floor space and machine type, every aspect plays a role in selecting a model that fits just right.

Remember, shrink wrap machines come in a variety of sizes and configurations, and the key to making the right choice lies in aligning machine capabilities with your specific business goals. Take your time, do the math, and consult with experts when in doubt—your operation will thank you for it.